Many facilities use pipelines to transmit substances other than oil or oil-related goods. These pipelines may eventually suffer damage from weathering, corrosion, or extensive use.

It is essential to repair the pipelines for the reasons listed below:

- Safety: Both humans and the environment may be at risk from damaged or leaking pipes. While corrosion and other types of degradation can erode the pipeline’s structure and raise the risk of failure, leaks can result in fires, explosions, and dangerous situations.

- Risk of Explosion: Overpressure incidents brought on by pipe deterioration may result in a fatal explosion. Gas or oil leaks from pipelines that come into touch with heat and flame can potentially result in explosions.

- Environmental Protection: Both humans and the environment may be at risk from damaged or leaking pipes. While corrosion and other types of degradation can erode the pipeline’s structure and raise the risk of failure, leaks can result in fires, explosions, and dangerous situations.

- Disruption of Services: Besides the risk of injury, ignoring pipeline maintenance allows the pipes to corrode and break down, leading to service disruptions.

-

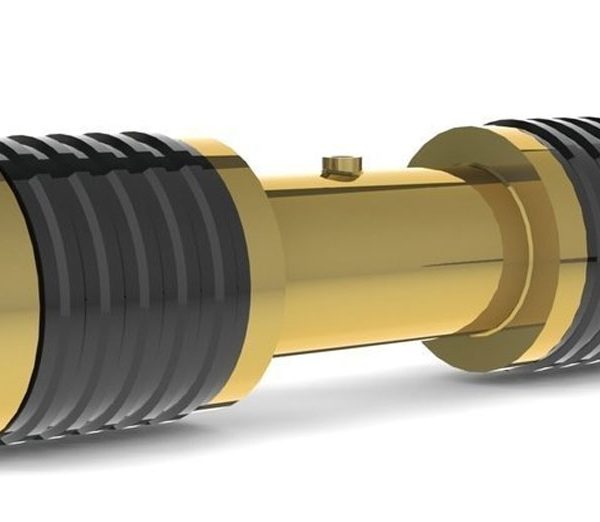

Wellube: Dual Tools

$25.00 -

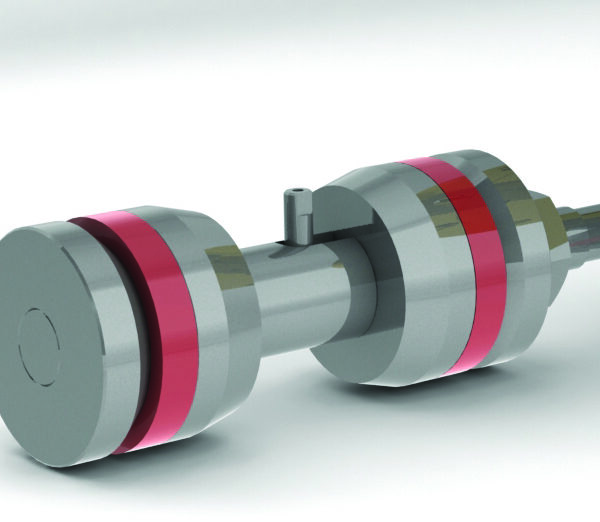

Wellube: Flange Weld Testers

$25.00 -

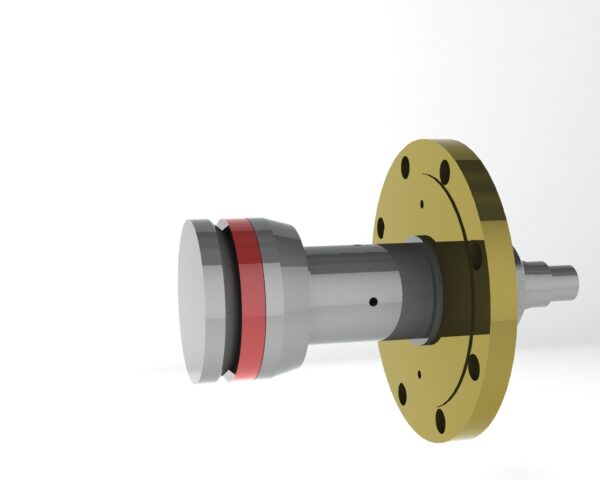

Wellube: High-Pressure Plug

$25.00

Pipeline Repair Process

The pipeline repair process includes the following:

- Internal Mobilisation

- Detection of pipe failure

- Notification of interruption

- Site inspection

- Repair work – selecting the appropriate method

- Testing

- Restoration

- Completion

- Repair planning

- Notice of restoration and work completion

Pipeline Repair Products

Repairs may be necessary if a pipeline leak or releases a product or if a flaw or anomaly is found that endangers the pipeline’s safety. The latter may be discovered through an accuracy evaluation, which the integrity management rule calls for.

Repairing pipeline defects and unusual situations that could pose a risk to the pipeline’s safety can be done in several ways by Wellube. They consist of

1. Weld Tester:

A suitable metal is deposited through welding to the pipe surface, the valve body or trim, or a pipe fitting in the shape of a layer as part of the weld tester pipeline repair process. This is further processed under different welding procedures like

- Internal Weld Tester

- Dual Tools

- Flange Weld Tester

- High Pressure Plug

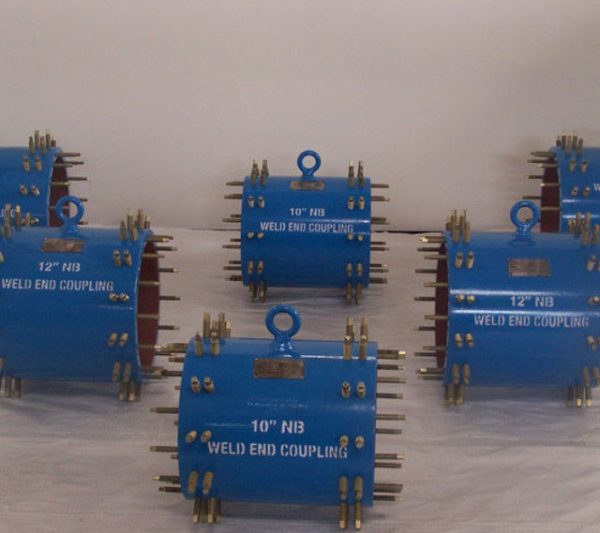

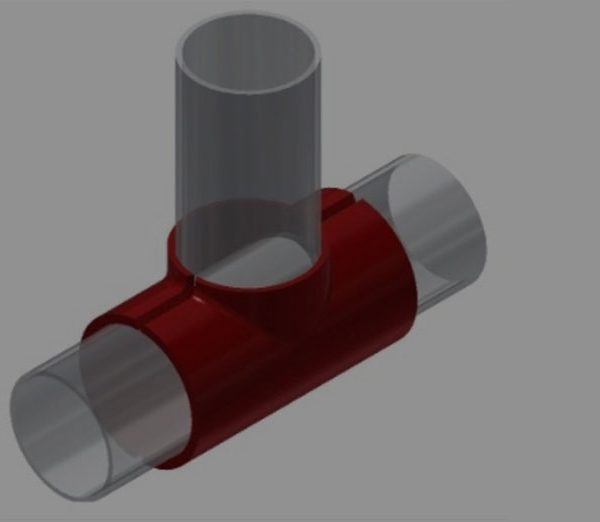

2. Pipeline Repair Clamps

Pipeline Repair Clamps are made to be installed on broken or leaking pipework, sealing the defect inside the clamp body and restoring pressure safety by engaging mechanical seals and locks on the healthy parent pipe. Wellube offers three types of repair clamp services which include:

- Split Sleeves Repair Clamp

- Structural repair Clamp

- Mechanical Coupling

3. Pipeline Custom Fittings

This includes:-

- Special fittings

- Reinforcing sleeves

- Hot tap fitting

- Pipeline repair clamps

- Line Stop fittings

- Full and Partial Reinforcing Saddles

4. Anti-Corrosion Products

Unparalleled end-to-end anti-corrosion coating systems are offered by Wellube, with each system created for a specific operating temperature, environment, and pipeline type. The procedure includes the following:

- Hot applies wax casing filler

- Cold-applied wax casing filler

- High-temperature anti-corrosion wrap

- Anti-corrosion wrap that is firm and can be used above ground and underground

FAQ's

What is the cost of pipeline repair services?

Several variables affect the price of pipeline repair services, including the degree of damage, the kind of repair necessary, where the pipeline is located, and the tools and materials required.

How to choose the right pipeline service provider?

Consider the experience, knowledge, reputation, customer service, safety record, and pricing of potential pipeline repair service providers before deciding. Also, it's critical to confirm their licensing and insurance.

Can pipeline repair services be done while the pipeline is in operation?

Depending on the type of repair needed, it is possible to perform pipeline repair services while the pipeline is still in use. To secure the security of the repair personnel and avert further pipeline damage, temporarily shutting down the pipeline can be necessary for some circumstances.