Enhancing Industrial Efficiency with Wellube's Expert Services for Online Valve Insertion

The successful operation of systems is essential in the large environment of industrial activities. A valve controls the flow of gases and liquids while preserving the equilibrium of industrial processes, acting as unsung heroes amidst sophisticated machinery and complicated operations. It is impossible to undervalue the importance of valves, and any disturbance in their performance can result in expensive downtime and inefficiency.

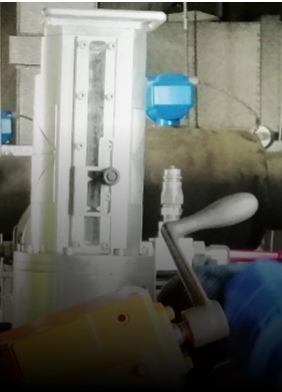

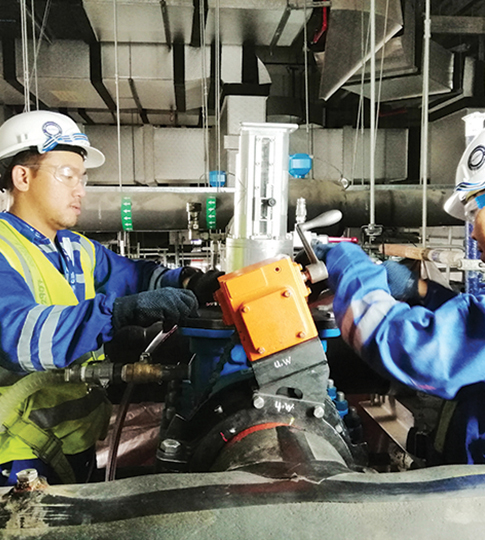

Wellube, a reputable engineering service provider and a recognised authority in the field of online valve insertion, steps in at this point. Wellube is a leader in providing seamless online valve insertion services that optimise industrial systems and raise operational efficiency to new heights. The company is known for its reputation for precision engineering and cutting-edge technology.

We go into the topic of valve insertion and discuss how important it is to industrial systems in this blog. We examine the problems with conventional valve upkeep techniques and the revolutionary potential of online valve insertion. We learn how Wellube’s solutions function as catalysts in boosting industrial efficiency, reducing downtime, and guaranteeing system integrity by focusing on their knowledge and cutting-edge services. As we set out on this adventure, we explore the art and science of valve insertion and learn how Wellube’s specialised services impact the industrial environment. So let’s explore the field of precision engineering and learn how online valve insertion enables businesses to run at an unmatched efficiency level.