Avoid downtime with Wellube - Expert contractor for pipe freezing services

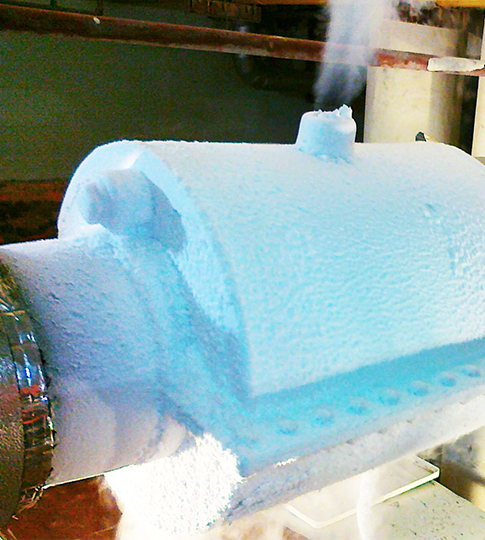

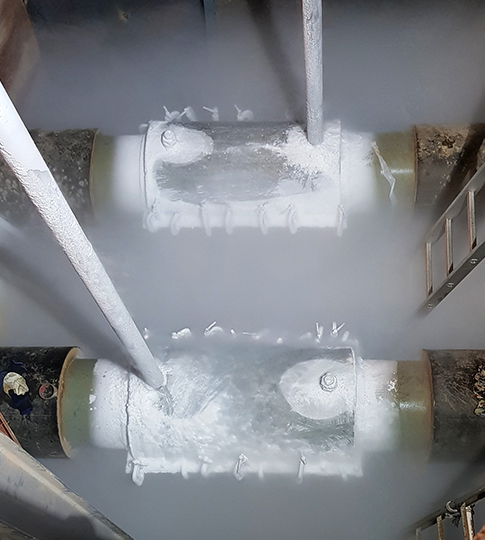

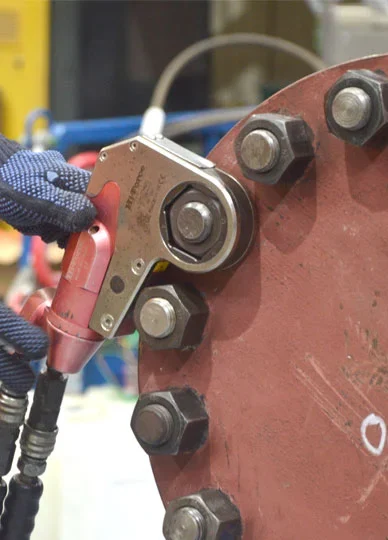

Pipe freezing is a modern technique for pipeline modification and repair that eliminates the need for full system shutdowns. Pipe freezing is started by rapidly cooling the pipe’s exterior, the fluid inside solidifies into an ice plug, isolating the specific section for maintenance and repair operations.

Pipeline Freezing method is particularly advantageous when shutdown valves are unavailable or when working in remote locations. Pipe freezing enables selective isolation of pipeline segments ensuring continuous operation of the remaining system, and is highly effective for small-diameter pipes. For large-diameter pipe freezing (DN150 or larger), specialized equipment and tailored engineering considerations are employed.

The process involves reducing the pipeline temperature below the fluid’s freezing point using high-performance refrigerants, with liquid nitrogen being a prevalent choice. As the cooling commences, the fluid forms an ice plug that halts flow, thereby creating a controlled environment for precise repairs or modifications.

With Wellube as your trusted pipe freezing contractor, you gain access to cutting-edge solutions that minimize downtime and optimize operational efficiency across petrochemical, oil & gas, and other critical industries. Our commitment to rigorous safety protocols, quality assurance, and precision engineering has earned the confidence of leading companies across the UAE, Qatar, and India.