The expertise of skilled professionals

Every successful project involving precision engineering relies on the experience of qualified specialists. As a renowned leader in the field, Wellube is aware of the critical role that their team of engineers and technicians plays in producing outstanding results. Wellube’s expert professionals, who are dedicated to perfection and never stop learning, are what give them their reputation for accuracy and dependability.

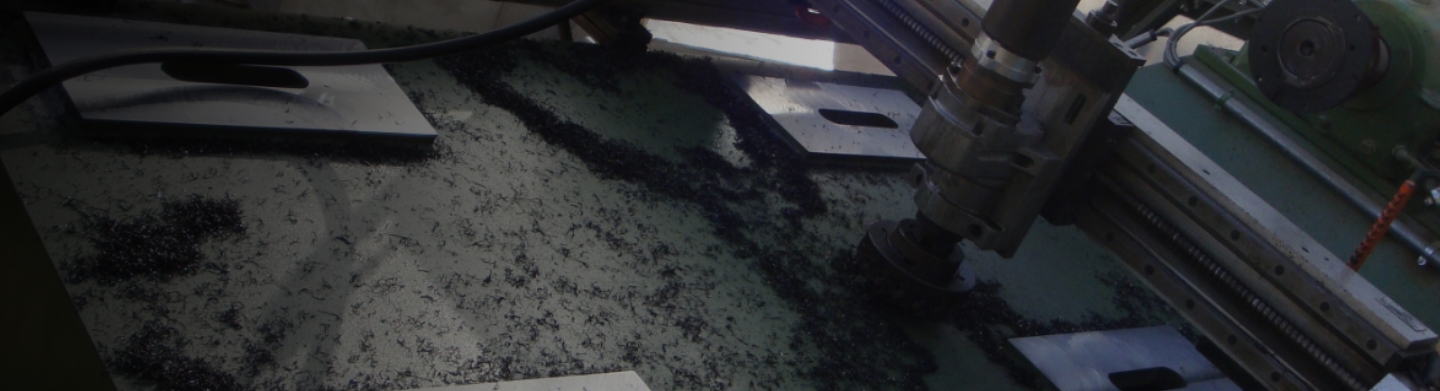

1. Technical Proficiency:

Wellube’s team of knowledgeable experts thoroughly understands the fundamentals of precision engineering. They are qualified to manage challenging industrial tasks with finesse thanks to their specialised expertise in milling and drilling methods. Their technical expertise equips them to handle difficulties successfully, ensuring that each task is carried out precisely and with attention to detail.

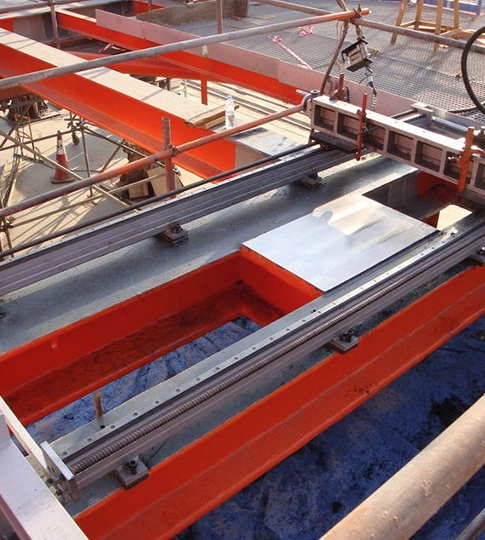

2. Experience:

Precision engineering requires much experience, and Wellube’s staff members have a wealth of it. Their crew is skilled at addressing various requirements and scenarios because they have experience working on varied projects across numerous sectors. They are better able to give creative solutions and produce higher results because of their significant experience.

3. Ongoing training and development:

The staff at Wellube is committed to fostering a culture of ongoing learning and development. They ensure their staff members stay current on the most recent business trends and technology developments by providing frequent training programmes and workshops. This commitment to skill development strengthens their competence and keeps them at the cutting edge of precise engineering techniques.

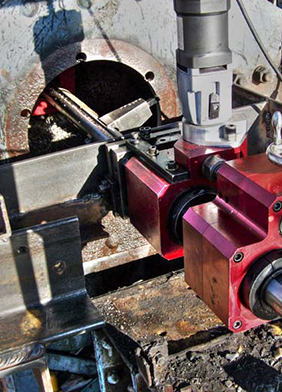

4. Problem-solving skills:

Strong problem-solving abilities are essential in precision engineering. The experts at Wellube have an astute analytical mindset and the capacity to think critically under pressure. They approach every assignment with a focus on problem-solving, looking for innovative solutions to get the highest level of accuracy.

5. Collaboration and Teamwork:

The experts at Wellube are aware of how essential teamwork and collaboration are to producing smooth results. They collaborate effectively, exchanging knowledge and skills to ensure that every project facet adheres to accuracy and quality standards. The total effectiveness and results of their work are improved by the synergy that this collaborative approach produces.

6. Client-Centric Approach:

The knowledgeable staff at Wellube prioritises contact with clients and is sensitive to each project’s particular requirements. They guarantee that the project’s goals, timetable, and specifications are precisely met by keeping open lines of contact with clients.

7. Adaptable and Agile:

Adaptability is crucial in the changing realm of precision engineering. The experts at Wellube are adaptable and agile, quickly changing with the needs and circumstances of a project. Even in difficult settings, they are able to manage complex projects with ease thanks to their versatility.

At the heart of Wellube’s dedication to accuracy is the knowledge of qualified professionals. Successful milling and drilling operations are built on technical expertise, experience, lifelong learning, problem-solving skills, teamwork, client-centric mindset, and adaptability of their workforce. Wellube is a trusted partner for precision engineering solutions thanks to its amazing team of experts, who constantly produce accurate and dependable outcomes.