Specifications

- Designed and manufactured to most standard material grades. Other special material grades can be considered upon request

- Sizes from ½” NS to 42” NS and pressure range up to ANSI 2500

- Design life for 25 years with Galvalum III anodes

- Marine epoxy as standard or to client’s specification

- Quick and easy in-situ installation

- Buna-N, Viton, and other seal options

Benefits

- Repair clamps preserve the pipeline’s integrity and increase its maximum permissible operating pressure (MAOP) capacity.

- Manufactured in accordance with particular pipe specifications and design guidelines.

- The repair clamp offers as much strength as or more than the host pipework.

- Protection in a variety of challenging operating situations is provided by sturdy construction and coating. The coating can be provided in accordance with client needs.

Application

- Process piping

- Infield flowline

- Trunk pipelines

- Subsea repair

- Risers

Choose the Right Structural Repair Clamp for Your Infrastructure Needs

- Pipes, whether for water or gas, are prone to damage and leaks and must be fixed immediately to avoid further complications.

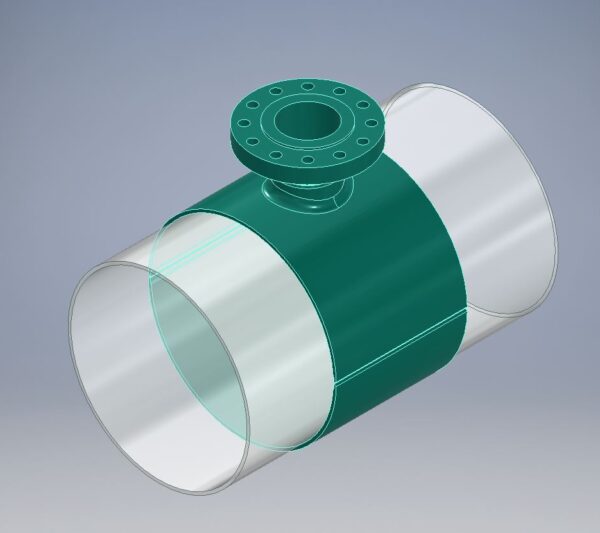

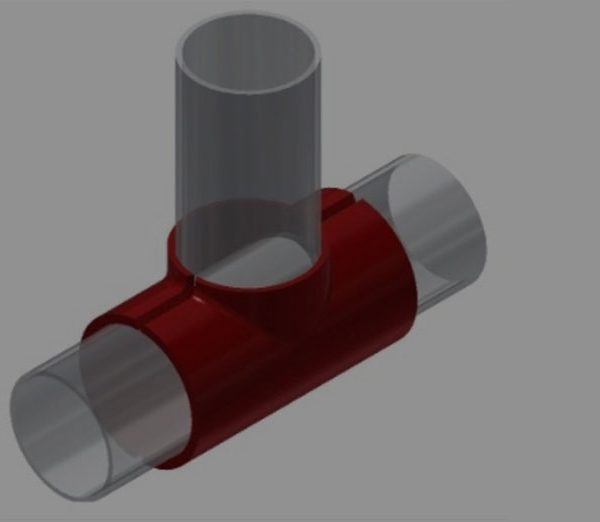

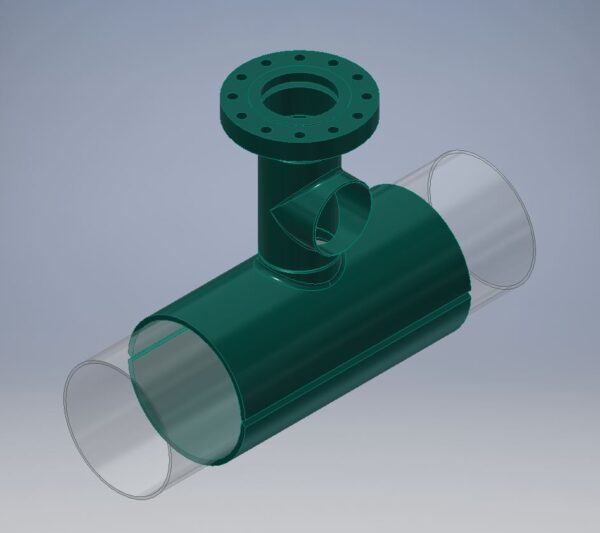

- A pipe repair clamp is a very useful instrument for mending pipes. It is a form of clamp that, as the name implies, keeps the pipe in place while it is being repaired or a new branch is being connected to the existing pipeline.

- Pipelines can be repaired while they are in operation or in a non-operational state using a repair clamp. Pipes of all sizes and materials can be easily repaired with repair clamps.

- When grout is utilised, Structural Repair Clamps provide pressure containment and radial support to the pipe. In order to provide axial constraint and structural integrity, a Pressure Containment Clamp can be configured with taper locks. The locks are installed in opposing pairs, grasping the pipe on both sides of the fault. The locks are designed to transfer the entire axial force of the pipe to the clamp body, allowing it to handle all pipeline separation stresses.

The Art of Processing Structural Repair Clamps: Engineering Ingenuity Unleashed

- Transferring axial loads from the pipeline into the clamp body increases structural integrity and relieves longitudinal stresses from the damaged pipeline segment, and locking grip collets reinforce the pipeline.

- It is possible to provide Structural Repair Clamps with single or double rows of seals with test ports to ensure the integrity of the seals before they are delivered to customers. Additionally, grouting ports may be added as an option.

How long will repair clamps lasts?

- The quality of the clamp, the materials utilised, the working circumstances, and the maintenance procedures used can all have an impact on how long structural repair clamps last. In general, the lifespan of well-designed, well fitted structural repair clamps can range from a few years to several decades.

- Exemplary repair In general, clamps made of corrosion-resistant materials, such as stainless steel or specialised alloys, have great endurance and can survive challenging environmental conditions. Longevity of the clamps is greatly increased by routine maintenance and inspections. Engineers can guarantee the clamps’ continuing efficiency and replace them if necessary by swiftly addressing any signs of wear, corrosion, or damage.

Benefits of Structural Repair Clamps

- Repair clamps preserve the pipeline’s integrity and increase its maximum permissible operating pressure (MAOP) capacity.

- Manufactured in accordance with particular pipe specifications and design guidelines.

- The repair clamp offers as much strength as or more than the host pipework.

- Protection in a variety of challenging operating situations is provided by sturdy construction and coating. The coating can be provided in accordance with client needs.

Application

- Process piping

- Infield flowline

- Trunk pipelines

- Subsea repair

- Risers

General Specification

- Designed and produced using the majority of common material grades. On request, further unique material grades can be taken into account.

- ANSI 2500 pressures and sizes up to 1/2″ NS.

- 25-year design life with Galvalum III anodes.

- Marine epoxy is available as standard or per client request.

- Installing in-situ is quick and simple.

- Viton, Buna-N, and other seal choices