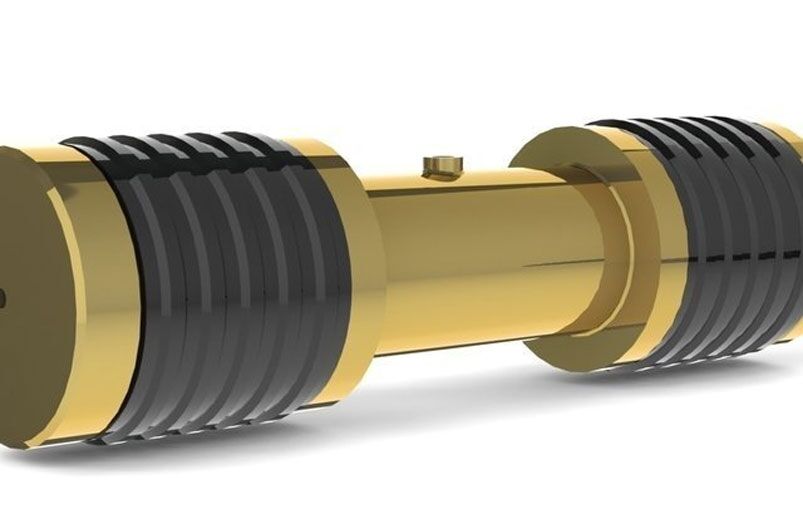

More details about Dual Tools:

Features

- Independently inflated tyre seals

- Designed to withstand 5 barg differential pressure

- Vent port for pressure monitoring and safe venting

- Three effective barriers

- Front and rear tyre inflation pressure 15 barg

- The internal annulus can be pressurised to 30 barg

- Easily installed and operated

- Designed with generous radial clearance to cope with typical internal obstructions such as weld bends and ovality

- Temporary isolation protection for hot work repairs

- Conducts isolation and weld testing combined

Simplify your complex pipeline projects with Wellube’s Dual Tools.

In pipework, specialised tools that integrate numerous functions into one tool are referred to as the “dual tool” idea. As a result, fewer distinct tools are required, and the process of maintaining or repairing pipes is streamlined. These tools are made to carry out numerous operations sequentially or concurrently. Dual tools frequently combine various features, including cutting, welding, grinding, inspection, and more, making piping operations efficient and affordable. In the pipework business, Wellube is renowned for offering cutting-edge dual-tool solutions.

Understanding Dual Tools- A Game Changer in Pipework

An annulus 6″ long is included in the Dual Tool idea between the two seal tires. It is a feature that enables incorporating a double block and bleeds feature to give a confirmed vapour barrier. Additionally, it has a central vent outlet that can be used to examine or vent potential gases securely.

It has three extremely effective seals once it is powered up and is made to endure a 5 barg differential pressure. Up to 36″, a complete selection of conventional Dual Tools is offered.

Functions and applications that dual tools can handle

Dual tools in the pipework industry provide various functions and applications, allowing for adaptability in multiple tasks. The following are some of the most typical functions and applications that dual tools can handle:

- Cutting: Dual tools can be used to cut pipes, tubes, and other materials. To achieve clean and accurate cuts, they may use revolving blades, plasma cutters, or precision cutting systems.

- Welding: Dual tools with welding capabilities enable users to join pipes and fittings quickly. They may comprise welding torches, electrodes, or other welding devices to enable accurate and dependable welds.

- Surface Preparation and Grinding: Some dual tools have grinding capabilities for prepping surfaces, removing burrs, or smoothing out jagged edges. They might use abrasive attachments, wheels, or grinding discs for efficient material removal.

- Testing and Inspection: Dual tools like cameras, sensors, or measurement equipment can incorporate inspection capabilities. Operators can use these features to inspect the inside or outside of pipelines, find flaws, measure distances, or find leaks.

- Pipe Rehabilitation: Dual tools may include specific cleaning, coating, or lining functionalities for pipe rehabilitation. To restore the integrity and performance of pipelines, they can clear away debris, use protective coatings, or put in liners.

- Flange Handling: When installing or maintaining pipework, dual tools explicitly made for flange handling can help bolster or unbolt flanges, ensuring perfect alignment and tightness.

- Pipe Beveling and Facing: Some dual tools have beveling and facing capabilities that allow users to precisely bevel or face pipe ends in preparation for welding or joining.

- Pipe Freezing: Dual tools may have pipe-freezing features, allowing temporary pipe separation without bringing the system to a complete stop. For upkeep or repairs, this feature is helpful.

- Pressure Testing: Dual tools may have capabilities for piping system pressure testing. To evaluate the consistency and effectiveness of the system, they can offer connections, valves, and gauges.

- Bolt Tensioning: By precisely applying and controlling the tension in bolts, dual tools created for bolt tensioning may guarantee appropriate riveting of flanges and connectors.

How to choose the right Dual tool for your pipework needs?

Choosing the best dual tool for your plumbing requirements necessitates careful consideration of several criteria. Here are some guidelines to help you make an informed decision:

- Know your requirement: Determine the tasks and applications the dual tool must handle. Consider the functions required for your pipework tasks, such as cutting, welding, inspection, or grinding.

- Safety: Prioritise dual tools with safety measures to safeguard operators and foster a secure working environment. Safety guards, automated shut-off systems, and integrated safety procedures are a few examples.

- Assessing Quality and Reliability: Look for dual tools made by recognized companies known for their trustworthy, high-quality products. Consider the tool’s robustness, performance, and long-term dependability while reviewing customer comments.

- Easy to use and Ergonomics: Consider the tool’s design and ergonomics when determining its ease of use. Ensure the controls are simple to understand, comfortable to operate, and user-friendly. Look for features like user-friendly interfaces, adjustable handles, and ergonomic grips.

- Training and assistance: Consider the manufacturer’s technical assistance, user guides, and training materials. Ample instruction and assistance ensure you can use the dual tool well and deal with problems.

- Budget considerations: Consider the dual tool’s features, quality, and long-term worth when assessing its cost-effectiveness. While comparing pricing from various vendors, remember how crucial it is to spend money on a solid, long-lasting tool.

- Warranty and service:: Verify the manufacturer’s warranty conditions and the availability of post-purchase service and assistance. A strong warranty and dependable customer care can give customers peace of mind and support if problems should occur.

2-in-1 Solution with Wellube’s Dual tool

Due to their knowledge, experience, cutting-edge solutions, a wide selection of tools, quality, dependability, safety emphasis, customizable possibilities, first-rate customer support, and a successful track record in the business, Wellube is regarded as the finest in the industry for delivering dual tool services.

Key feature:

- Independent tyre seal inflation.

- Built to endure a 5 barg difference in pressure.

- Vent port for safe venting and pressure monitoring.

- Three strong barriers.

- 15 barg for the front and rear tyres’ air pressure.

- At 30 barg, the interior annulus can be pressured.

- Simple to install and use.

- Large radial clearance accommodates common internal impediments such as weld bends and ovality.

- Protection from temporary isolation during hot job repairs.

- Combines the performance of isolation and weld testing.

Why is Wellube recognised best in the industry?

Due to several characteristics, Wellube is regarded as one of the top suppliers of dual tool services in the piping sector.

- Expertise and Experience: Wellube offers a wealth of experience in the upkeep and repair of piping. They have a group of competent experts who know the difficulties involved in piping operations.

- Wide Selection of Dual Tools: Wellube provides many dual tools to accommodate different piping applications. With options for cutting, welding, grinding, inspection, and more, their wide-ranging tool selection offers adaptability and flexibility for various applications.

- Quality and Reliability: Wellube provides high-quality instruments adhering to industry standards.

- Compliance and Safety: Compliance with safety regulations is a top priority for Wellube while designing and using its tools. Their dual tools have safety features and follow strict safety guidelines.

- Proven Track Record: Wellube has a documented history of delivering dual tool systems effectively in numerous piping projects across the globe. They have gained the trust and respect of their peers in the business thanks to their track record of dependable results and customer satisfaction.