Features

- Eliminates the need to weld caps or flanges to carry out a leak test

- Simple, straightforward installation and operation

- Installed and activated in a matter of minutes

- Suitable for use with most test mediums

- Robust construction ensures years of trouble-free operation even in the harshest environments

Specifications

- Large section high-quality seals ensure a leak-tight seal, even in corroded pipework

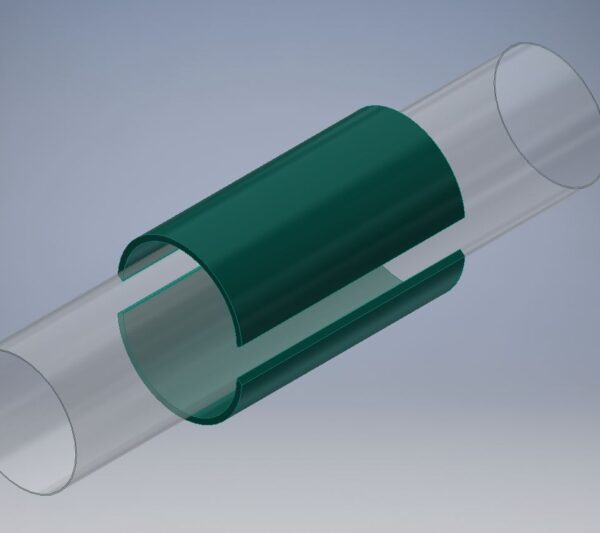

- Designed with generous radial clearance to cope with typical internal obstructions such as weld bends and ovality

- Easily installed pre-hot work operations to provide a verified vapour barrier

- Suitable for installation in horizontal, vertical, and inclined piping

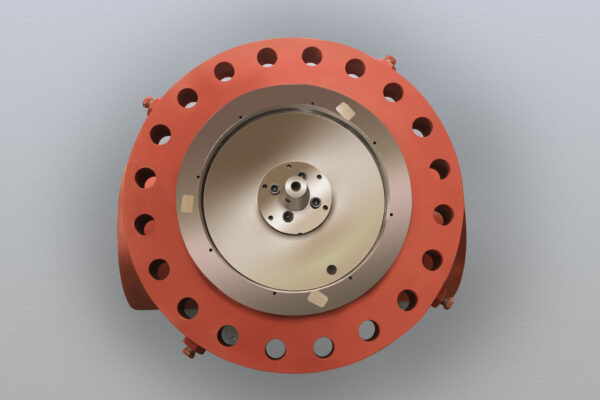

- A full range of standard High-Pressure Plugs is available up to 30” Class 1500 for immediate delivery, complete with pressure test reports

- Design, manufacture, and test to client requirements up to Class 2500

- Can be custom designed to suit the specific application for higher pipe sizes with the option of hydraulic and mechanical actuation

Applications

- Sealing test plug for high pressure hydrostatic testing of pipe, pipelines and pressure vessels

High-Pressure Plugs- Installation and Application in Pipework System

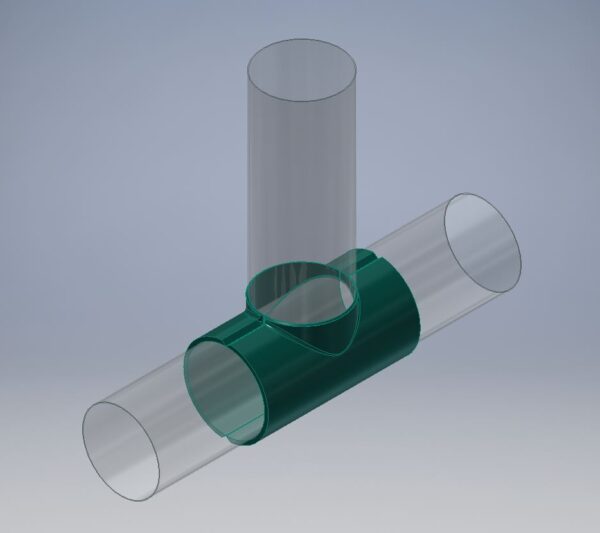

High-pressure pipe plugs are constructed mostly of a metal body linked to additionally strengthened rubber. These pipe plugs are mechanical devices used to seal and plug the end of a pipe, allowing for hydrostatic testing and pressure barrier isolation.

High-pressure pipe plugs isolate piping systems during testing, maintenance, and repair. High-pressure pipe plugs can be used to test piping systems while they are being built and to bypass problematic piping portions. Before putting piping systems into service, these high-pressure plugs can be used to ensure they are leak-tight. They also test each pipe connection individually, including welds, couplings, mechanical joints, and gaskets.

Usage of High Pressure

- Pipe plugs, known as high-pressure Test plugs, are offered commercially by PlugCo. Their use size ranges from 100 mm to 2000 mm, and they are available for such purposes. These pipe plugs are generally employed in high-pressure applications where ordinary inflating rubber plugs cannot hold.

- Up to 30″ Class 1500 standard high-pressure plugs are readily available for worldwide shipping with pressure test results. Additionally, we create, produce, and test products up to Class 2500 per client request. For larger pipe sizes, they can be specifically constructed to fit the purpose, with the choice of hydraulic or mechanical actuation.

- A line of Pipe plugs known as high-pressure Test plugs is offered commercially by Wellube. These pipe plugs are generally used in high-pressure applications where ordinary inflating rubber plugs cannot hold.

Application of High Pressure Plugs

High-pressure pipe plugs are meant to resist high pressures without rupturing or leaking and are typically constructed of a sturdy stainless steel body encircled by an inflatable rubber bladder. They are frequently employed in specialised settings, including desalination plants. Safe pipework isolations are made possible by the Grip-lock and Posi-seal TM technologies.

High-Pressure Plugs are frequently used during piping and process equipment maintenance and modification, including hydrostatic pressure testing without requiring flanges or blind flanges. They can help you save time, resources, and labour.

What are the correct procedures for installing high-pressure plugs?

An instruction manual for installing high-pressure Pipe Plugs is provided below:

- Ensure the pipeline is clear of all pollutants, sharp items, and debris. By doing this, you can be confident that the Pipe Plug will correctly seal and not sustain any harm.

- Insert the Pipe Plug into the pipeline slowly and with care. To avoid harming the plug or the pipeline, insert it straight, not at an angle.

- The size of the Pipe Plug you require for your pipeline should be determined. You can achieve this by determining the pipe’s inner diameter.

- After releasing the pressure in the pipeline, remove the Pipe Plug once the task is over. To avoid harming the pipeline, carefully remove the stopper.

- To prevent the Pipe Plug from sliding, install the support. Verify that the plug is securely held in place by the brace.

- Execute the scheduled maintenance or repairs.

- Inflate the Pipe Plug to the Wellube-approved maximum inflation pressure.

Following these instructions, you can ensure that high pressure Pipe Plugs are put correctly and that your pipeline is secure. It’s crucial to remember that it’s always preferable to be safe than sorry regarding pipeline safety.

Key Features of Wellubes high-pressure plugs

- Removes the requirement to weld caps or flanges to perform a leak test.

- Installation and operation that is simple and uncomplicated.

- In a matter of minutes, it was installed and activated.

- Compatible with the majority of test mediums.

- Large radial clearance accommodates common internal impediments such as weld bends and ovality.

- Pre-hot work procedures that are quickly deployed and create a validated vapour barrier.

- High-quality seals provide a leak-tight seal even in damaged piping and large sections.

- Suited for installation in piping that is horizontal, vertical, and inclined.

- Even in the roughest settings, robust design provides years of trouble-free operation.

Industries of application

Many businesses that require high pressure sealing or containment of fluids or gases frequently employ high-pressure plugs. High-pressure plugs are used in a variety of sectors, including:

- Oil & Gas

- Chemical Industry

- Power Generation

- Aerospace and Aviation

- Manufacturing and Machinery

- Automotive Industry

- Research and Development

Why pick Wellube

The best option is Wellube’s high-pressure plug services. They are fully qualified and experienced to manage your needs securely and efficiently. Their knowledgeable specialists are experts at putting in, taking out, and maintaining high-pressure plugs. You can rely on them to put safety first and adhere to tight guidelines to secure everyone and everything. The fact that they provide specialised solutions that are catered to your particular needs is fantastic. Additionally, they verify quality at every stage and employ premium materials. You may get thorough services from Wellube that are also affordable, which will ultimately save you time and money. Why search elsewhere, then, when Wellube provides everything you need?

Availability :

Availability :