Client SK Engineering and Construction (SKEC) Country Fujairah, United Arab Emirates (UAE) Year 2023 Details Wellube’s hot tapping and line stopping service is a cost-effective way of enabling repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either…

24” Leaking Offshore Gas Pipeline Arrested Using Online Leak Sealing Solution

Client Leading Offshore Oil and Gas Company Country United Arab Emirates (UAE) Year 2021-2022 Details Wellube successfully delivered a comprehensive turnkey online leak sealing solution for a leading oil and gas client, ensuring uninterrupted operations and enhanced reliability. The project involved…

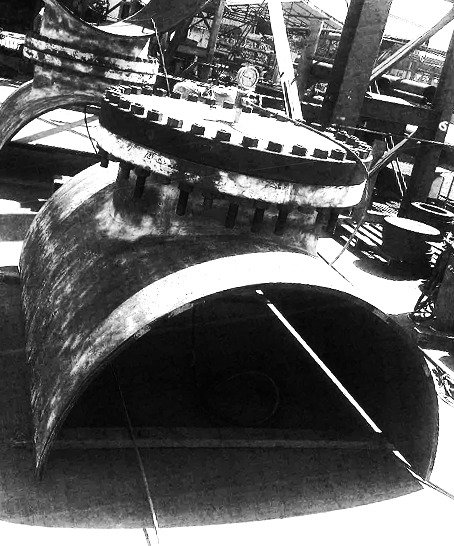

52’’ X 52’’ Horizontal Hot Tap Completed on India’s Largest Flare Stack

Client Leading Petrochemical Company Country India Year 2023 Service details Wellube’s hot tapping and line stopping service is a cost-effective way of enabling repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either a planned or emergency basis. Our hot tap operation…

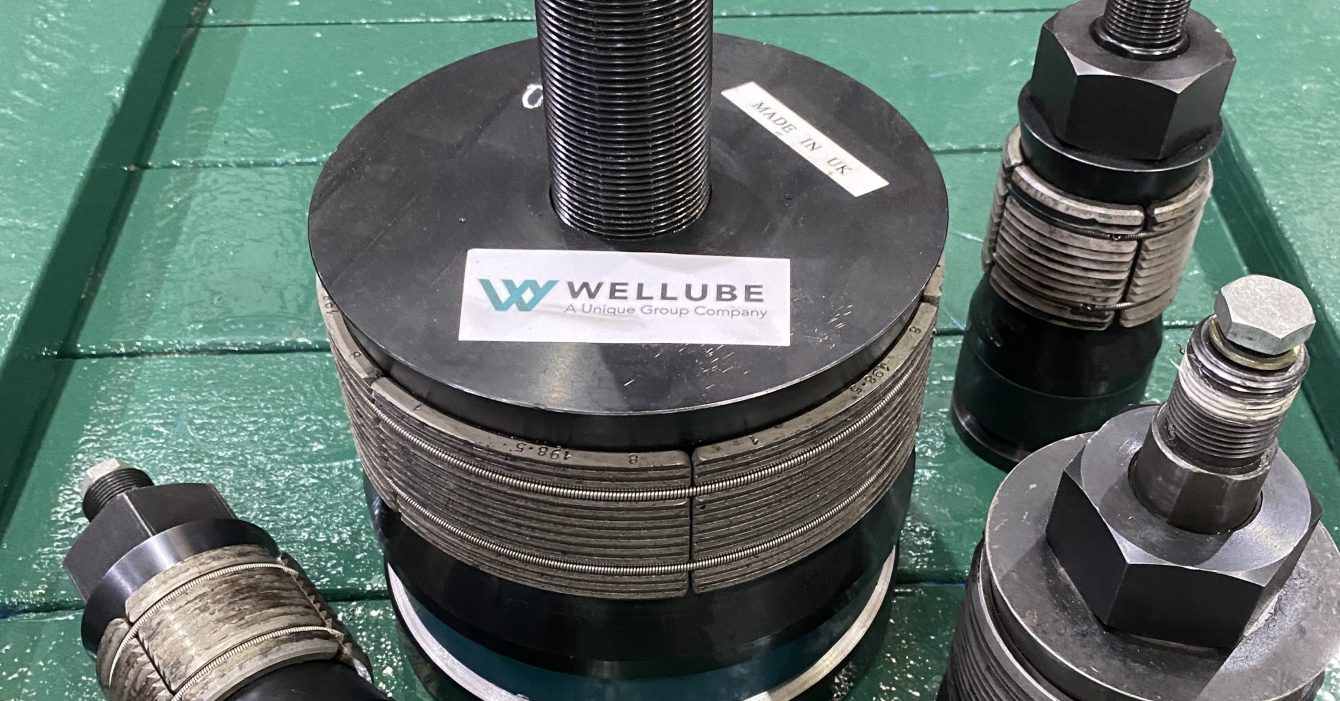

Wellube’s Specialised Testing and Isolation Solutions for Weld Integrity

Client Oil and Gas Asset Owner Country UAE Year 2023 Service details Wellube’s Flange Weld Testers provide accurate localized pressure testing of new flange welds – a key benefit during pipeline modifications and old pipework repairs. Our Mechanical isolation plugs lugs are…

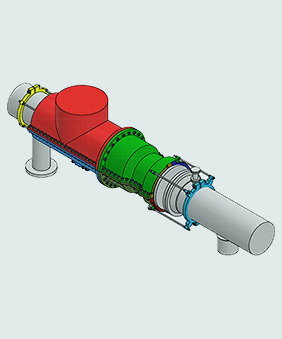

Successful Rerouting of a 14” High-Pressure Pipeline in India via Tandem Double Double Line Stop

Client Leading LPG transmission company Country India Year 2023 Service details Wellube’s hot tapping and line stopping service is a cost-effective way of enabling repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either a planned or emergency…

Hot Tapping & Double Line Stop Work for Rerouting of Existing Pipeline

Client Mumbai Aviation Fuel Farm Facility Pvt. Limited (MAFFL) Country Mumbai, India Year 2018 – 2022 Service details Wellube’s hot tapping and line stopping service is a cost-effective way of enabling repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either a…

Bespoke Hot Tapping Solution Completed for Energy Optimization Project

Wellube successfully supported a client’s energy efficiency measures on a major chilled water infrastructure, by installing temperature and pressure sensors through bespoke hot tapping solution.

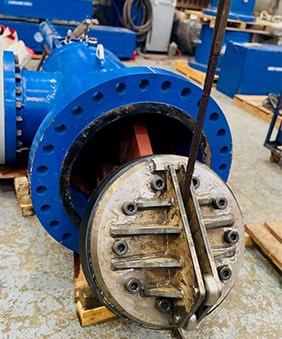

36” Crude Oil Line Isolated Using Line Stopping

Wellube completed line plugging on a 36”150# crude oil line through inline tee to provide isolation during shut down to cold cut and replace the existing section of the pipeline.

62” X 4” Tee Enclosure Clamp Seals Leak with Zero Production Loss

Wellube successfully sealed a sea water leak in the Tee branch of a client pipeline using a 62” x 4” Tee enclosure.

Flare Line Leak Sealed Online with a 24” Large Enclosure Clamp

Wellube successfully repaired a flare line with multiple sections of corrosion using a 2.9m long 24” enclosure clamp, with zero interruption to production.