Your choice in custom pipeline fitting: Wellube

A pipeline custom fitting is a unique component that is specifically developed and manufactured to match a pipeline’s specific section or demand. These fittings are custom-made to give a precise fit and function that is adapted to the pipeline’s specific specifications and intended application.

Pipeline custom fittings can be constructed from various materials, including steel, plastic, and composite materials. Fittings can be designed and manufactured to withstand various pressures, temperatures, and fluids.

Elbows, tees, reducers, couplings, flanges, and other components used to join and connect pipeline sections or adjust their configuration are examples of custom fittings. They may also comprise specialised components such as bends, transitions, and expansion joints to support pipeline bends, diameter changes, and other non-standard requirements.

Engineers and fabricators with experience in pipeline systems and materials generally create custom fittings. Depending on the material and intricacy of the fitting, they can be created using a variety of techniques like welding, forging, casting, and machining.

-

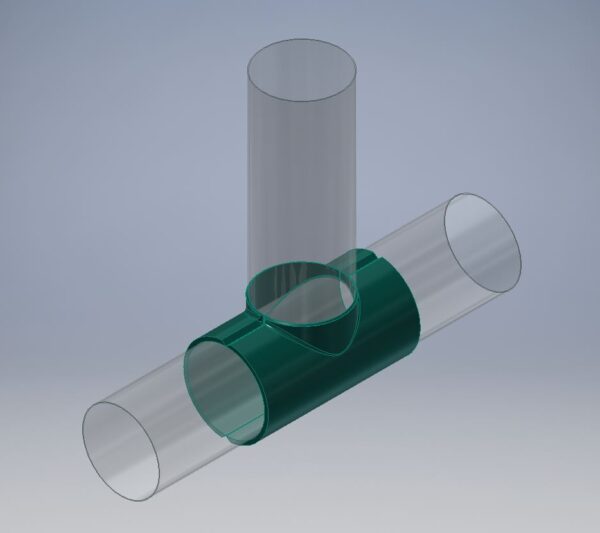

Wellube: Full and Partial Reinforcing Saddles

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ. -

Wellube: Special Fittings

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ. -

Wellube: Reinforcing Sleeves

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ. -

Wellube: Hot Tap Fittings

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ. -

Wellube: Pipeline Repair Clamps (Leak Sealing)

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ. -

Wellube: Line Stop Fittings

Original price was: 28,00 د.إ.25,00 د.إCurrent price is: 25,00 د.إ.

Pipeline custom fitting process

Wellube specialises in custom pipeline fittings that are adapted to the needs of its clients. Wellube’s custom fitting creation process begins with an in-depth review of the client’s needs, followed by a complete design and engineering phase. To construct the bespoke fitting with the appropriate materials and specifications, Wellube also employs cutting-edge production techniques such as forging, casting, and machining. Before installation, each fitting is subjected to stringent quality control and testing to guarantee that it fulfils the highest safety and performance standards.

Wellube pipeline custom fittings process includes:

- Special Fittings

- Reinforcing Sleeves

- Hot Tap Fittings

- Pipeline Repair Clamps

- Line Stop Fittings

- Full and Partial Reinforcing Saddles

Special Fittings

Some pipeline repair and maintenance challenges necessitate a one-of-a-kind solution. Line-stopping equipment, hot tapping and plugging, and other off-the-shelf devices are not always sufficient.

Our engineers can create a unique solution to meet your specific needs. Three-way connections, angle fittings, and more options are available. We’ll take the time to understand your problem, work through budgets and timelines, and deliver the correct solution at the right time.

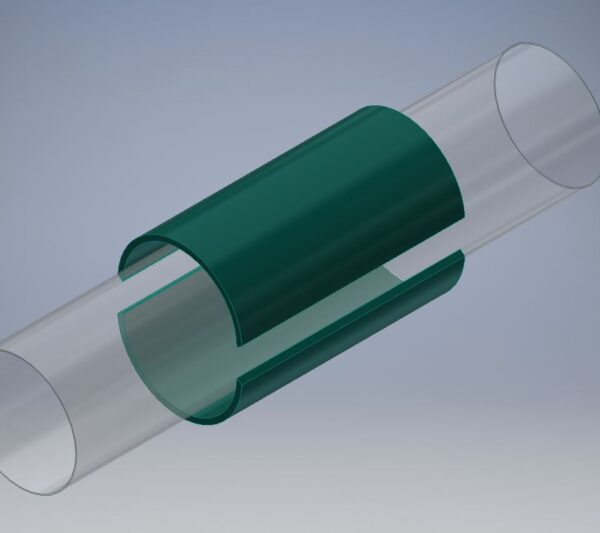

1. Reinforcing Sleeves

Uni-Forge manufactures and supplies reinforcing sleeves to repair or strengthen pipes that have been damaged by internal or external corrosion, scrapes, dents, fractures, or bad welds.

The sleeves can be custom-designed to offer structural reinforcement at maximum pressure

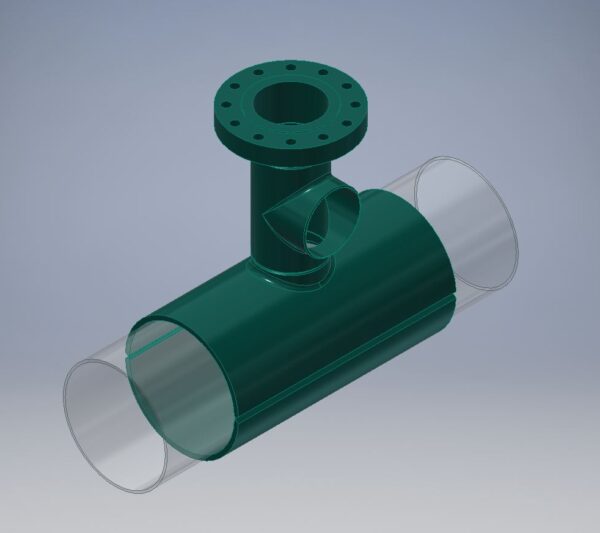

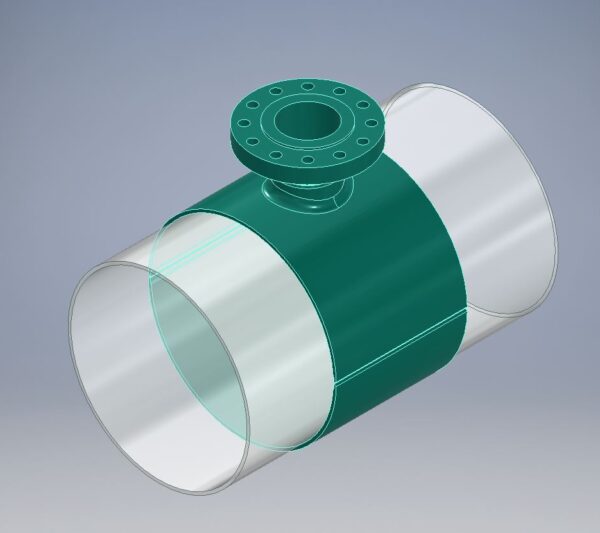

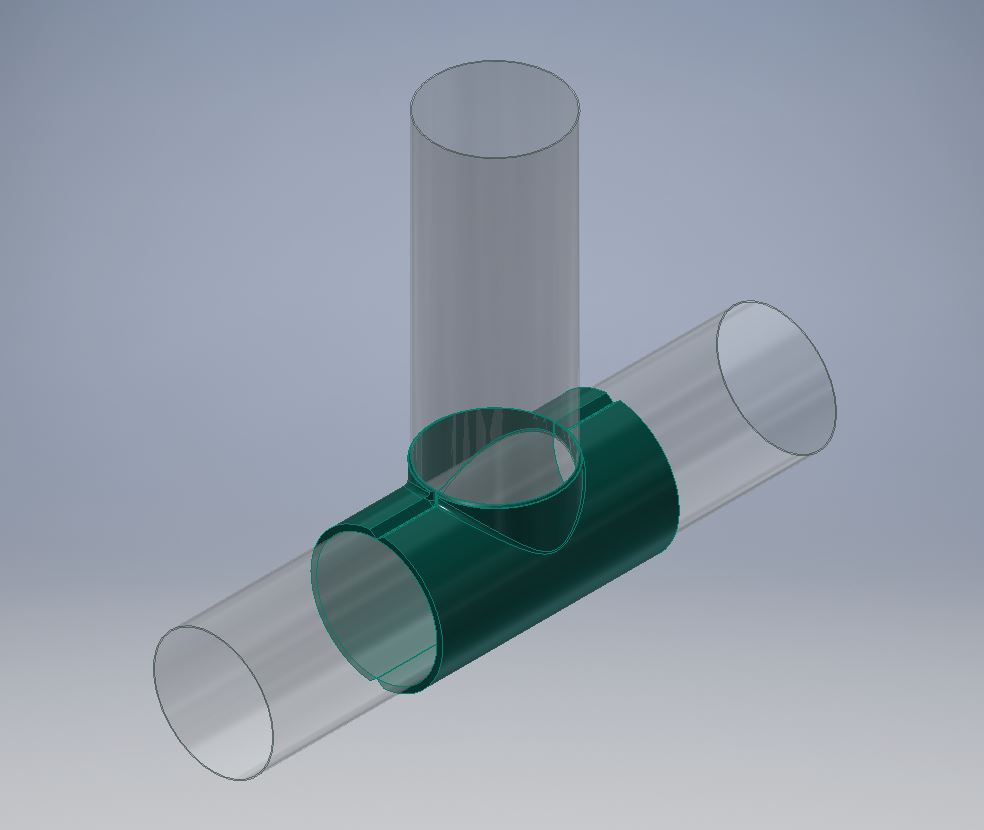

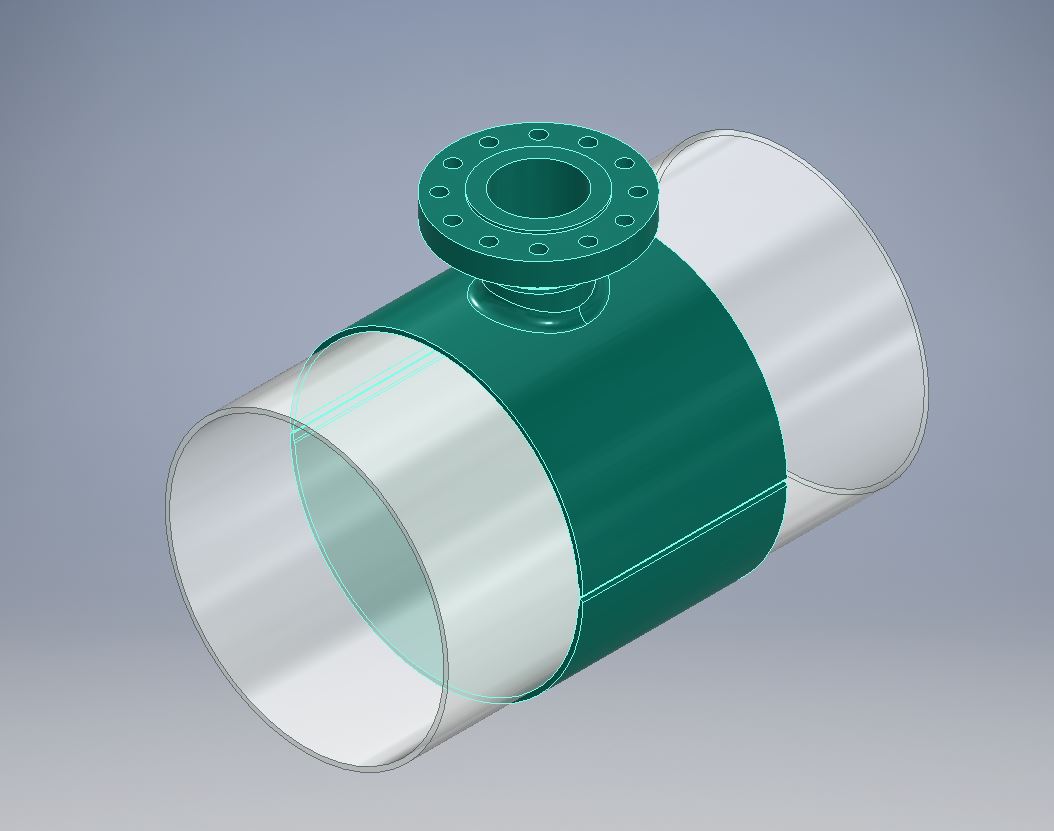

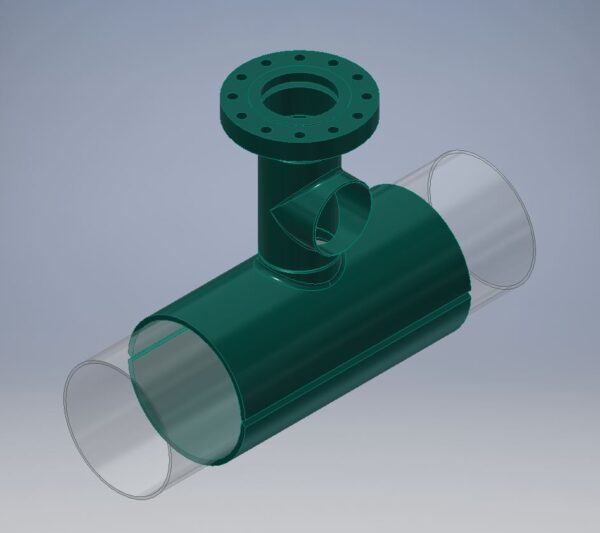

2. Hot Tap Fittings

Full-branch split tees from Uni-Forge are designed for equipment tie-ins, lateral connections, and line extensions using a permanent full-bore valve without shutdown.

Our fittings are available in various diameters ranging from 2″ to 48″ and are furnished with an ANSI Class 150, 300, 600, or 900 welding neck flange. Larger diameters and pressure ratings are available to accommodate any requirement.

Uni-Forge can meet all of your hot tap tee demands with personalised customer care and on-time delivery.

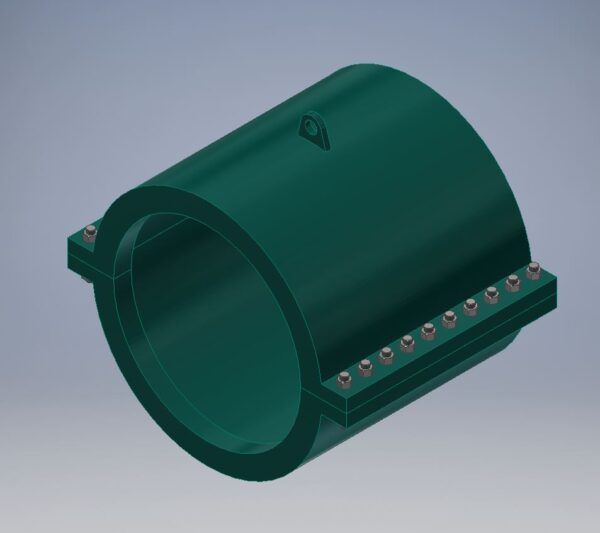

3. Pipeline Repair Clamps

Uni-Forge pipeline repair clamps provide a speedy and cost-effective solution. This add-on solution is suitable for both temporary and permanent repairs to damaged or leaking pipelines.

Our ASME VIII-compliant fittings can be utilised on both low and high-pressure applications, as well as a wide range of pipeline materials.

4. Line Stop Fittings

When pipeline repair or maintenance is required, Uni-Forge line stop fittings are the right answer. Our line-stopping equipment is built to be safe for almost any distribution pipeline, including oil, natural gas, and others. Personalised customer assistance to assist with pipeline repair line stop installation.

Full and Partial Reinforcing Saddles

Wellube offers the Uni-Forge series of partial and full encirclement reinforcing saddles in various sizes to meet multiple pipeline repair and maintenance requirements. Extruded outlet tees are offered for branch sizes up to 48″ NPS, while fabricated branches are available for greater sizes. Wellube’s extrusion procedure eliminates the weld between the header and branch, which can be challenging to inspect using radiography. This design element increases the dependability and endurance of Uni-Forge fittings, lowering the possibility of leakage or failure.

Why can you trust Wellube's services of Pipeline Custom Fitting?

1. Committed to pipeline and customer safety: For the energy sector, we offer premium standard and customised pipeline repair and maintenance supplies. Offering items such as line stops, split tees, hot tap fittings, hot tap pipe plugs, high-pressure pipeline fittings, reinforcing saddles, and others, we are dedicated to meeting the industry’s strict deadline requirements while still producing high-quality goods. Outstanding customer service is available right away from our staff.

2. Repair and Maintenance Experts: With a focus on extruded materials for pipeline reinforcement, our workforce has vast experience in pipeline fitting engineering, design, and production. The stress risers present in welded-type tees are eliminated, and our procedure enables complete radiographic evaluation.

3. Custom pipeline fitting within budget and on time: At Wellube, we produce fabricated branches and other especially specialised pipeline items, such as repair sleeves, high-pressure tapping equipment, cold tapping equipment, and many others. To satisfy the deadlines, unique quality criteria, and design regulations of our customers, we’ve made investments in machining and welding equipment for custom manufacture.

To ensure we can rapidly meet client requests, we have built a local supply chain to acquire any grade of steel or other parts needed in the manufacturing process. Additionally, we can meet any particular product testing or heat treatment requirements of our clients thanks to our connections with important inspection, testing, and specialty service suppliers.