Key benefits

- Can be easily installed without prepping the pipe ends

- The couplings are designed with radial and axial screw bolts allowing alignment of the two pipe ends together whilst compressing the sealing gasket to eliminate leaks

- The coupling can be permanently welded on-line

- Capable of withstanding axial forces when welded of when the pipeline is axially supported

- Selection of sealing gaskets available

Dependable mechanical couplings from Wellube

- All the things on the frame, load-bearing bodywork and chassis of the motor vehicle and trailer that are used to connect them together to create a combination of vehicles or an articulated vehicle are referred to as mechanical connection devices and components. For the connection or use of the mechanical coupling device or component, there are fixed, moveable, or detachable pieces.

Applications of mechanical coupling

What is the purpose of mechanical coupling? Can’t we just weld two shafts together or use a gearbox instead? “No” is the answer. Couplings offer both advantages and disadvantages. Mechanical coupling cannot be replaced by gears or welded joints. They are used for the following purposes:

- 1. Transmit powers:

The driver and driver shaft are connected by a mechanical coupling. In this manner, they transfer power as a joint between the driver and the driven shaft. - 2. Protection against overloading:

Overload protection Mechanical connection restricts torque transfer from one shaft to another. They safeguard the driver and the driver system from jamming and overloading in this manner.

- 3. Absorb shock:

Any shocks or vibrations that travel from the driving element to the driven element can be dampened by a shaft coupling. This feature lengthens the setup’s service life and lessens component wear. - 4. Absorb misalignment:

Nothing is flawless. Engineering tolerance is included with manufactured parts. It is difficult to expect perfectly aligned shafts in the actual world. Welding input and output shafts is therefore not a suitable practice if the shafts are misaligned. A coupling can compensate for misalignment between connected shafts.

Types of Mechanical Coupling

There are many different sizes and shapes for couplings. While some of them are specially created for incredibly specialised conditions, others perform fine for generic applications.

Understanding the features and variations of the various types of couplings can help you make an educated decision. The following coupling types and how they operate are covered in this section:

- Sleeves coupling

- Flanged coupling

- Split-muff coupling

- Flexible coupling

- Oldham coupling

- Universal coupling

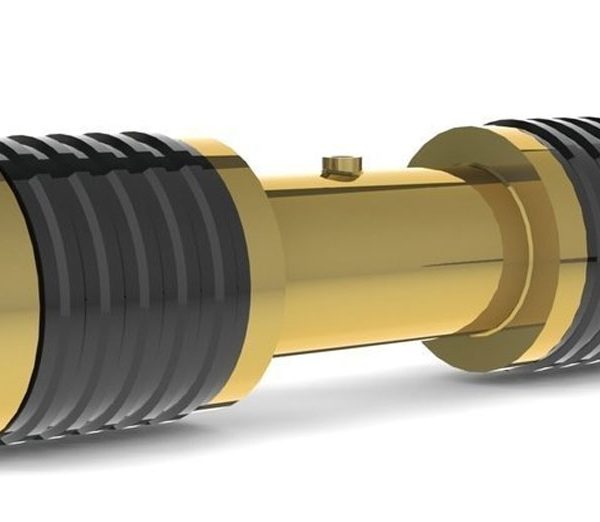

- Gear coupling

- Fluid coupling

Industrial Application

The joining or connecting of two or more mechanical systems or components is referred to as mechanical coupling. It is frequently employed to transmit motion, torque, or power between rotating or linearly moving parts in a variety of industrial applications. The following are some frequent industrial uses for mechanical coupling:

- Power transmission

- Automotive industry

- Machine tools

- Material Handling

- Pimping systems

- Wind turbines

- Robotics and automation

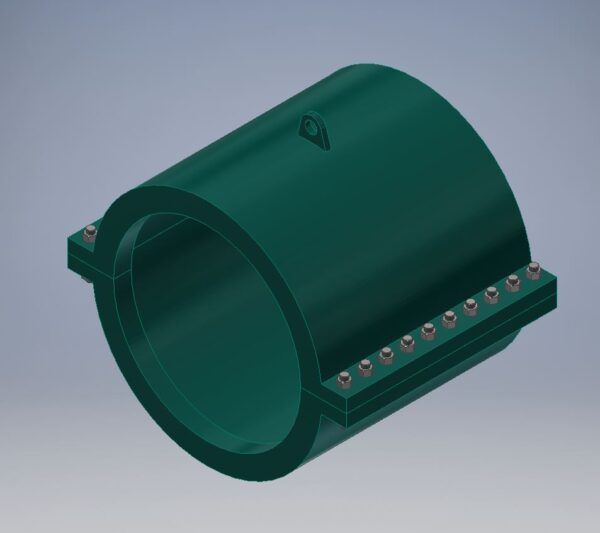

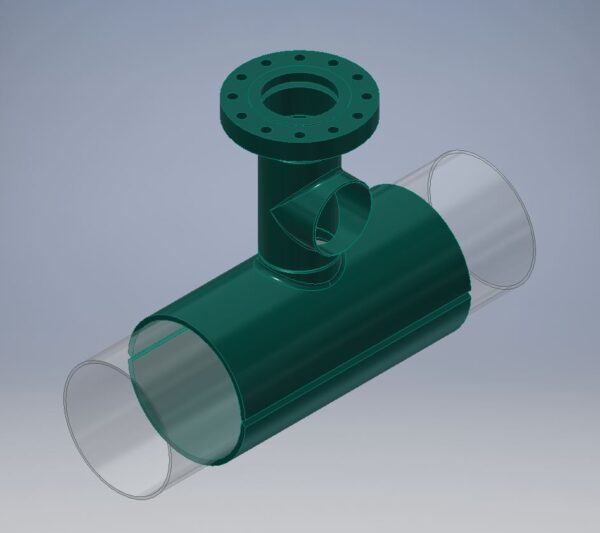

Why choose Wellube’s mechanical coupling products

Mechanical Coupling from 3″ nb to 48″ nb, rated up to ANSI 900, are available from Wellube and are suited for pipelines carrying water, oil, gas, and steam. available in ASTM A193 Gr. B7 Screw Bolts and API 5L/ASTM A106 or similar body materials.

Key benefits:

- Installation is simple and doesn’t require preparing the pipe ends.

- The couplings’ axial and radial screw bolts allow the two pipe ends to be aligned while also compressing the sealing gasket to stop leaks.

- The coupler may be online permanently welded.

- The pipeline is welded or when the pipeline is axially supported, capable of withstanding axial forces.

- Available selection of sealing gaskets.

Availability :

Availability :