DIPS – Prioritize Safety While Ensuring Pipeline Integrity

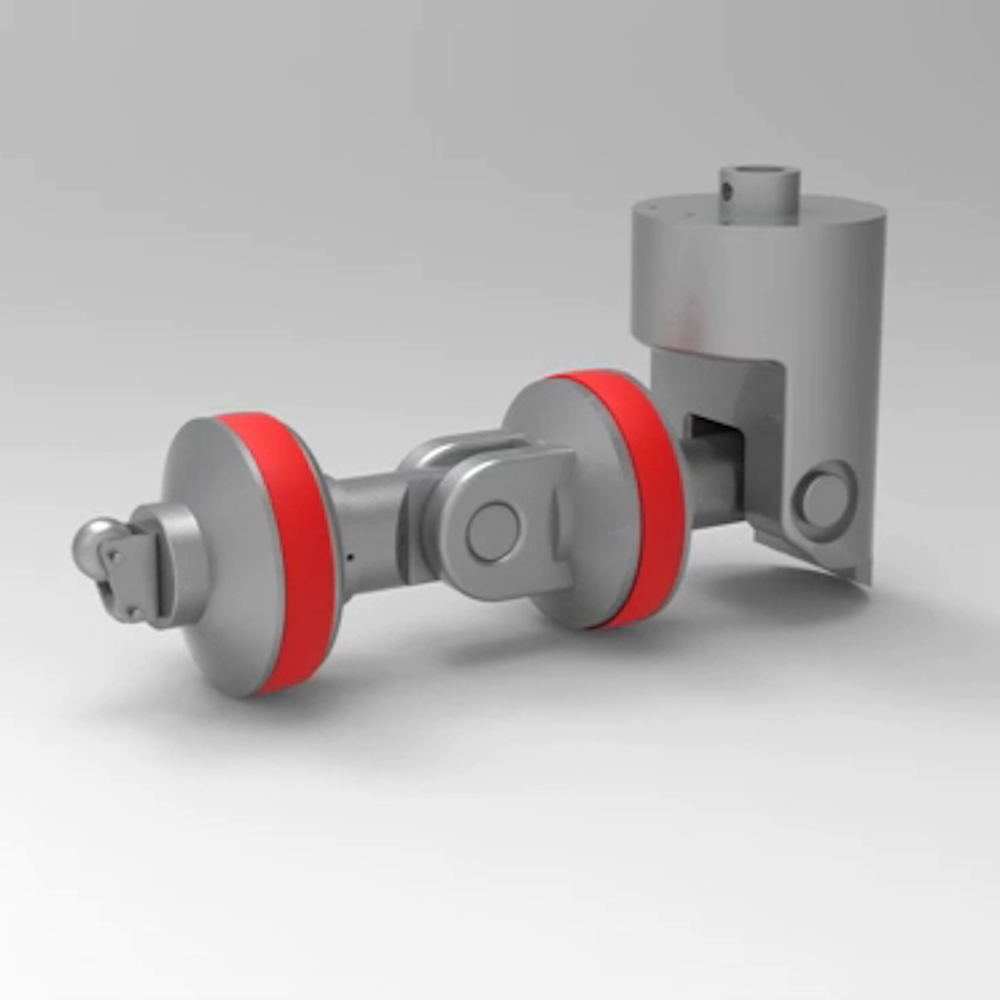

Double Isolation Pipeline Stopper (DIPS) represents a significant advancement in line stopping technology, offering unprecedented safety and reliability for critical pipeline interventions. This innovative system provides dual-seal isolation with integrated pressure testing capabilities, establishing a new standard for pipeline maintenance without shutdown.

Online pipe intervention with double isolation

Providing peace of mind and added safety assurance, Double Isolation Pipeline Stopper (DIPS) enables intervention of live pipelines in the oil & gas, petrochemicals, and energy industries reliably. DIPS supports maintaining the pipeline integrity and is the next-gen advancement over double position line stop. This solution provides a fail-safe isolation using single hot tap intervention, without the need for additional tapping for bleed and vent ports.

DIPS reduces risk and provides complete reassurance to clients for line isolation in critical environments. During the intervention process, the pipeline can be operated normally with a temporary bypass.

The DIPS technology incorporates a double isolation design that creates two independent barriers within the pipeline. This redundant sealing mechanism dramatically reduces the risk of breakthrough during maintenance operations, particularly crucial when working with hazardous media or in environmentally sensitive areas. Between these two isolation seals, a pressure testing chamber allows real-time verification of isolation integrity throughout the entire intervention. Unlike conventional line stopping methods, our DIPS solution enables continuous monitoring of seal performance, providing operators with immediate feedback on isolation status. This capability proves invaluable during extended maintenance operations where seal degradation might otherwise go undetected until failure occurs.

Specifications

Double Isolation Pipeline Stopper builds upon your requirement providing versatility. DIPS solution covers

- Customizable to any pipeline dimensions

- In-house capability ensures full turnkey support for even the most demanding situations

- Hydraulically activated seal provides feedback and enables pressure testing

Applications

Suitable for various pipeline operations such as:

- Valve Installation or Replacement

- Pipe repair, replacement or decommissioning

- Pipe re-routing

- Flow Meter installation

- Draining of pipelines

- Pressure Control Switch installation

- Pipeline inspection

- Determine product in a pipeline

- Air Relief Point

VIDEO: Introducing Double Isolation Pipeline Stopper (DIPS)

Why

Choose

Wellube?

If you’re planning a project but are not sure of the best way to make it happen, tap into the wealth of experience that we have to offer. Working together, we can achieve innovative line intervention turnkey services to suit your requirements.

Wellube’s Double Isolation Pipeline Stopper (DIPS) service is the safest way to enable repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either a planned or emergency basis.

Wellube’s 20+ years of experience in the field across various industries has informed every aspect of the DIPS design, resulting in a solution that addresses real-world challenges encountered in pipeline interventions. Developed through extensive research and field testing by Wellube’s global engineering team. The system is compatible with multiple pipeline materials including carbon steel, stainless steel, and various alloys, with pressure ratings tailored to specific application requirements.

By implementing DIPS technology for your next pipeline intervention, you eliminate compromise between operational safety and maintenance efficiency. The system’s dual-barrier protection and continuous monitoring capabilities provide peace of mind while its streamlined design minimizes deployment time and resource requirements. Trust Wellube’s DIPS solution to maintain your pipeline integrity without operational disruption, setting a new benchmark for isolation reliability in the industry’s most demanding applications.