Efficient & Safe Online Welding Services from Wellube

What is Hot Tap Online Welding?

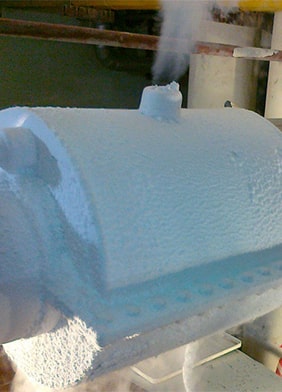

Creating a new connection to an existing pipeline or vessel that is under pressure or in use requires the welding method known as hot tap online welding, sometimes referred to as hot tapping or pressure tapping. The fluid or gas movement inside the pipeline can be repaired, modified, or installed entirely new using this method.

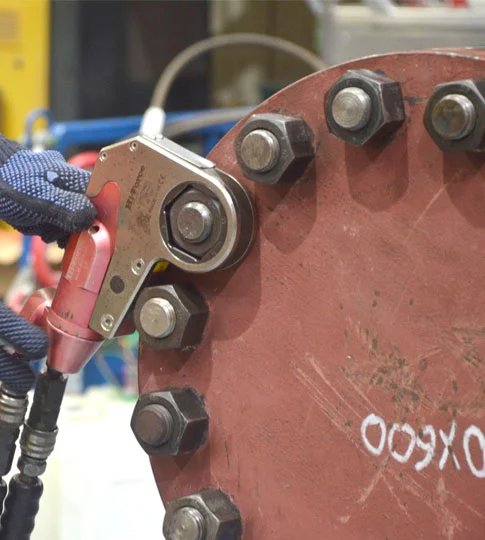

A hole is made in the existing pipeline or vessel using a specialised drilling device or cutting tool during the Hot Tap Online Welding procedure. The flow of the liquid or gas inside the pipeline is then managed by installing a valve at the site of the hole.

Several industries use hot tap online welding, including oil and gas, chemical, water treatment, and power production. Without shutting down the entire system, it offers a safe, affordable, and effective way to make repairs or upgrades to an existing pipeline or vessel.