Key Aspects to Keep in Mind When Planning a Hot Tap and Line Stop on Your Pipeline

Hot tapping and line stopping are essential techniques in the oil and gas as well as utilities industry for performing maintenance, repairs, or modifications on live pipelines. These procedures allow for work to be conducted without shutting down the entire system, minimizing production losses and reducing downtime.

However, planning and executing a hot tapping and line stop requires careful consideration and adherence to industry best practices to ensure safety, efficiency, and optimal results. In this technical blog, we will explore the top things to keep in mind when planning a hot tap and line stop on your pipeline.

-

Thoroughly Evaluate Pipeline Condition:

Before initiating a hot tap and line stop operation, it is crucial to assess the pipeline’s integrity and condition. Conduct a comprehensive inspection to identify any structural weaknesses, corrosion, or potential hazards. This evaluation will help determine the feasibility of performing the hot tap and line stop and ensure that the pipeline can withstand the additional stresses during the operation.

-

Engage Experienced Professionals:

Hot tapping and line stopping procedures involve complex engineering principles and precise execution. It is essential to engage qualified and experienced professionals who have expertise in these techniques. This includes engineers, technicians, and field personnel who have a thorough understanding of the pipeline system, relevant codes and standards, and the equipment required for the operation.

-

Determine Operational Requirements:

Clearly define the objectives and requirements of the hot tap and line stop operation. Identify the specific maintenance, repair, or modification tasks that need to be performed. Determine the required pipe diameter, flow rates, and operating pressures. This information will help in selecting the appropriate hot tap fitting, line stop equipment, and other necessary tools.

-

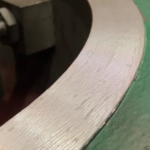

Select Suitable Hot Tap Fitting:

Choosing the correct hot tap fitting is critical to the success of the operation. Consider factors such as material compatibility, pressure and temperature ratings, and the fitting’s design and construction. Consult with experts to determine the most suitable fitting for your pipeline, ensuring it meets industry standards and complies with applicable regulations.

-

Develop a Detailed Execution Plan:

Create a detailed execution plan that outlines all the necessary steps, sequences, and timelines for the hot tap and line stop operation. Include a comprehensive risk assessment and mitigation strategy, taking into account potential hazards, safety procedures, and emergency response protocols. A well-defined plan helps ensure smooth coordination among the team members and minimizes disruptions to ongoing operations.

-

Communicate and Coordinate:

Maintaining effective communication and coordination is vital throughout the planning and execution phases. Establish clear channels of communication among all involved parties, including engineering, operations, maintenance, and safety personnel. Regularly update and inform stakeholders about the progress, challenges, and any changes to the execution plan. Open and transparent communication promotes collaboration and ensures everyone is aligned with the project objectives.

-

Conduct Operator Training and Safety Briefings:

Prior to initiating the hot tap and line stop, provide comprehensive training to the operators and field personnel involved. Train them on the proper use of equipment, adherence to safety protocols, and emergency response procedures. Conduct pre-job safety briefings to reinforce hazard awareness, emphasize safety measures, and address any concerns or questions raised by the team.

-

Monitor and Inspect Throughout the Operation:

Continuous monitoring and inspection are crucial during the hot tap and line stop operation. Regularly assess key parameters such as pressure, temperature, and flow rates

As a critical operation, it is essential that we take the utmost care to follow each step of these guidelines to ensure a seamless and safe hot tap/line stop operation. With over 25 years of experience in the industry, Wellube is at the forefront of providing flow management intervention and integrity solutions to customers globally. If you have a challenging project, you would like our support, contact us here.