Hot Tapping 101: The Basics

Hot tapping is the method of taking a new connection from an existing piping or pressure vessel while the section of pipe or vessel continues to operate. The whole operation is completed while the line is “live” or in its normal operating conditions.

Our unique range of specialist hot tapping equipment enables a connection to be made to a piping system or a vessel without shutdown or interruption to production.

Hot taps can be performed safely on most types of pipes, ranging from carbon steel to GRE. They can be carried out on systems containing oil, gas, fuel, steam, water, and many other line mediums with pressures up to 1480 psig @ 100 Deg F on normal cases. However, we are equipped to undertake jobs where the medium has a high temperature of up to 700 Deg F.

Advantages of Hot tapping equipment

- No shutdown is required and therefore no loss of production

- No loss of product within a pipe – No emission to the environment

- Reduced cost of planning of manpower and resources

- Coupled with a line stop operation, valves can be repaired/ inserted, or damaged /corroded pipe or fittings can be replaced or long stretches of pipelines can be re-routed.

Hot tapping process consists of:

- Hot tap fitting with the required branch & flange size.

- Ball or Gate Valve

- Hot tap machine with Cutter & Adaptor

The Six-step Hot Tapping Equipment Process

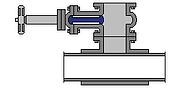

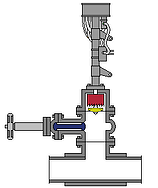

Step 1: Weld the fitting to the line and bolt the valve to the pipe fitting.

Step 2: Bolt the hot tap (HT) machine to the valve.

Step 3: Check for leaks in bolted connections by pressure testing through the hot tap adaptor. Make sure the valve is fully open throughout the testing.

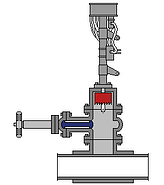

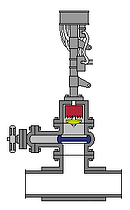

Step 4: Start cutting the pipe by advancing the cutter till the cut is complete. The section of the pipe which is removed is known as the “coupon.” This is retained by means of u-wires, which are attached to the pilot drill.

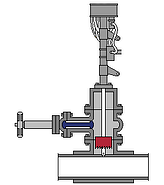

Step 5: Once the cutter has cut through the pipe, the hot tapping equipment or machine can be stopped. Withdraw the cutter into the hot tap adapter and close the valve.

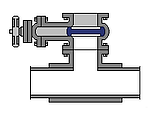

Step 6: Prior to removing the hot tapping equipment or machine, the pressure from inside the tapping adapter is bled off. The machine is then removed from the valve, and a new pipe outlet is established.

The Uptime Benefits of Hot Tapping

The process can be performed on almost any type of pipe that carries fluid under pressure, ranging from carbon steel to PVC. Adding new connections to a pipeline is not the only reason for doing hot taps. Product sampling points, pressure control switch installations, inspections, and draining pipes are just a few examples of hot tapping procedures. Not only it is cost-efficient, but it is also a safe and effective way to keep facilities up and running during repairs and upgrades to vital infrastructure.

Trust a Quarter-century of Hot-tapping Expertise

Experience and Quality fittings are critical to the success of any successful project. Manufactured in our own facilities, every fitting uses high-grade materials and our proven extrusion processes. To learn more about the process and the best options for quality pipe fittings and services, contact the Wellube team