Redefining Pipeline Intervention

This article was originally published as part of World Pipeline Magazine in November 2024.

Garry Kidd, Managing Director, Wellube, describes a comprehensive approach to pipeline intervention solutions, drawing on hot tapping and line stopping methods.

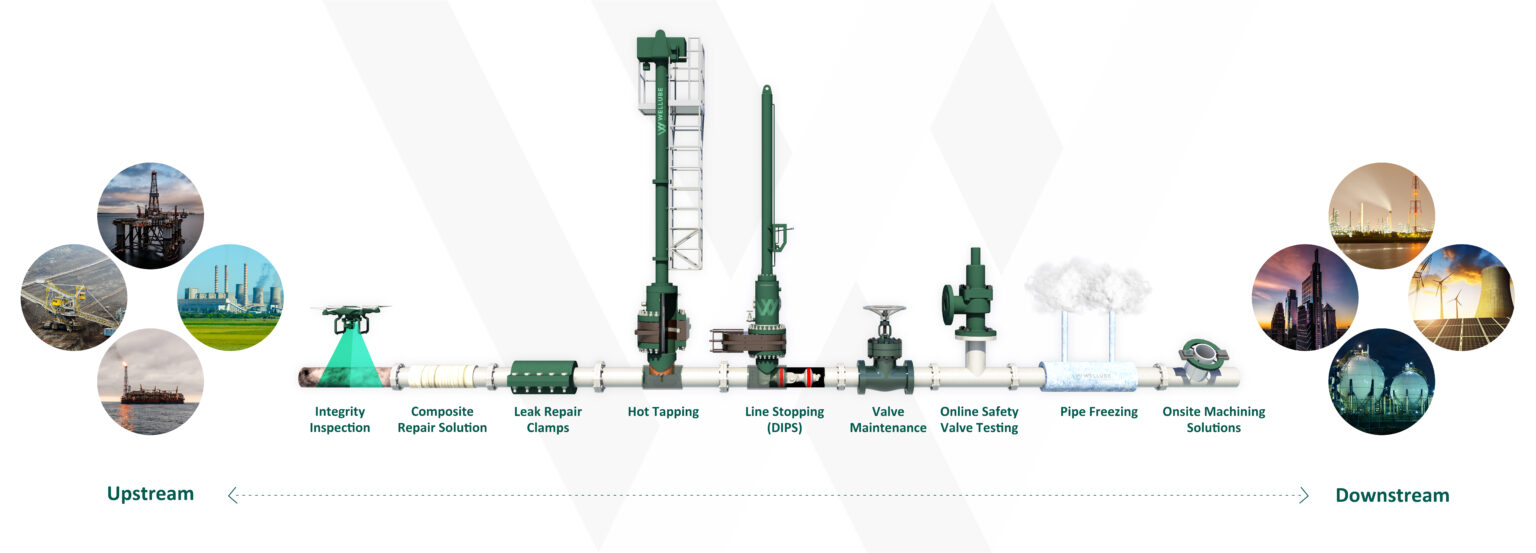

In the complex and ever-evolving oil and gas energy industry, safety, efficiency, reliability and integrity are paramount. For over 25 years, Wellube has been at the forefront of addressing these challenges through innovative flow management intervention, and integrity solutions. As a leading provider of pipeline isolation and intervention solutions, Wellube is committed to enhancing industry standards and best practices.

Advancing pipeline isolation

Wellube’s Double Isolation Pipeline Stopper (DIPS) represents a significant advancement in pipeline intervention technology. This innovation highlights Wellube’s dedication to enhancing safety and operational efficiency. DIPS represents a significant step change in pipeline intervention technology, providing a dual fail-safe isolation using a single-size-on-size hot tap intervention. Unlike traditional methods that require multiple tapping for bleed and vent ports, DIPS simplifies the process while significantly reducing associated risks. The development of DIPS was driven by the need for a more secure and efficient method of pipeline isolation in critical environments, such as those found in the oil, gas, and petrochemical industries. By eliminating the need for additional taps, DIPS not only reduces the operational risk but also minimises the time required for intervention, ensuring that pipelines remain functional with minimal disruption. DIPS has been designed to meet the highest industry standards, and its adoption by leading companies globally is a testament to its reliability. With third-party approval and an impeccable track record, DIPS provides peace of mind for our clients, allowing them to maintain pipeline integrity even during complex interventions.

Essential tools in pipeline management

Hot tapping and line stopping are critical services that Wellube provides as part of its comprehensive pipeline intervention solutions. These techniques allow for the maintenance, repair, and modification of pipelines without the need for shutdowns, which is crucial for minimising operational downtime and avoiding costly production halts. Hot tapping involves the installation of a connection to a live pipeline, enabling tie-ins, relocations, repairs, or the installation of new equipment. This method is invaluable for clients who require pipeline modifications while maintaining continuous operation. Wellube’s expertise in hot tapping has been demonstrated in numerous onshore and offshore projects, including the successful execution of six interventions on an aviation turbine fuel pipeline. This project required re-routing and decommissioning of existing 10 in. and 20 in. lines spanning kilometres. We completed the project with precision and adherence to stringent safety standards. Line stopping, on the other hand, involves temporarily blocking the flow in a pipeline to enable the installation of equipment such as valves or branches. Wellube’s line stopping solutions are engineered to ensure that the flow is safely diverted or isolated without interrupting the overall operation. In a recent project in Sudan, Wellube completed a double position line stop on a 32 in. gas flare line, allowing the client to install a butterfly valve and a tie-in valve without halting production. This operation, the first of its kind in north Sudan, highlights Wellube’s ability to deliver complex solutions under challenging conditions.

End-to-end asset integrity management solutions

Wellube’s approach to pipeline intervention goes beyond the immediate tasks of hot tapping and line stopping. Wellube offer end-to-end asset integrity management solutions that reduce our clients’ dependence on multiple vendors, ensuring a more coherent and controlled service flow. Selecting Wellube as the sole point of contact for a project simplifies communication and coordination, leading to a more streamlined process. With Wellube assuming full project responsibility, the risks of miscommunication and delays are significantly mitigated. The turnkey solutions provided by Wellube not only enhance cost efficiency by reducing the overhead associated with managing multiple vendors but also save time by enabling effective oversight and integration of all phases from design to implementation. Accountability is a key focus, with a strong emphasis on maintaining high quality and adhering to strict timelines. Clients benefit from specialised expertise and innovative solutions tailored to their specific needs. Additionally, the seamless integration of project components improves operational efficiency and performance, while Wellube’s management of procurement, installation, and commissioning simplifies logistics, thereby reducing complexity and potential challenges. A prime example of Wellube’s end-to-end asset integrity management was a project with one of India’s largest refineries. The client needed to connect a newly built flare stack to an existing pipeline, a task that involved connecting two 52 in. pipelines 15 m above ground and carrying hazardous Hydrogen Sulphide (H2S) gas. Wellube managed the project from initial enquiry through to the final execution, providing a fully integrated solution that included the design and supply of a custom 52 in. x 52 in. Split Tee Fitting, in-service welding, and a horizontal hot tap. The project was completed within the stringent timeline, meeting the highest safety standards and exceeding the client’s expectations.

Beyond pipeline intervention: comprehensive integrity solutions

While pipeline intervention remains a core service, Wellube’s expertise extends to a wide range of pipeline integrity solutions. The importance of maintaining the integrity of pipeline systems is essential for the safe and efficient operation of any facility, and Wellube focuses on delivering comprehensive solutions that address all aspects of pipeline integrity. Their advanced leak-sealing solutions are engineered to prevent leaks without necessitating system shutdowns, thereby maintaining operational continuity. In cases where complete isolation is required, their pipe-freezing technique provides a secure method for creating solid ice plugs within pipelines, facilitating necessary repairs or modifications. Additionally, Wellube offers extensive valve maintenance services, which are vital for ensuring smooth and reliable flow control within pipelines. For situations that demand precision engineering, their onsite machining services deliver high-quality results directly at the site, removing the need to dismantle equipment. To further protect pipeline integrity, Wellube’s corrosion protection solutions are tailored to extend the lifespan of pipeline.

Solutions for global clients

Wellube is known for delivering bespoke solutions that meet the specific needs of its clients. The company’s team of experienced professionals ensures that each project benefits from innovative and effective solutions tailored to the unique challenges presented. An example of Wellube’s ability to deliver customised solutions is a recent project at a leading airport infrastructure in Qatar. The task involved installing temperature and pressure sensors across a chilled water infrastructure as part of the client’s energy optimisation efforts.

A commitment to safety

Safety is at the core of every service provided by Wellube. The company’s unwavering commitment to operational excellence, competency development, and safety has resulted in a spotless record of zero lost time incidents. This dedication is evident in every project, from initial design to final execution. The introduction of the DIPS is a reflection of Wellube’s ongoing efforts to enhance safety in the industry. By providing a reliable method of pipeline isolation, DIPS sets a new standard for pipeline intervention, ensuring that operations can continue safely and efficiently, even in the most challenging environments. As the oil and gas industry continues to evolve, the demand for reliable, efficient, and safe pipeline management solutions grows increasingly critical. Wellube remains at the forefront of this industry, providing pioneering solutions that consistently meet and exceed client expectations. With over two decades of experience, a global network of highly skilled professionals, and a steadfast commitment to innovation and safety, Wellube is a trusted partner for companies seeking to ensure the integrity and efficiency of their pipeline operations. Whether the need is for pipeline intervention, integrity solutions, or a complete end-to-end asset management service, Wellube has the expertise, technology, and dedication to deliver exceptional results. By partnering with Wellube, clients are assured of a collaborative relationship focused on achieving success at every stage of their projects.

For more information check out our solutions page.