Online Leak Sealing on Wellhead Flange Leak in Costa Rica

| Client | Geochem (Geo Thermal – Energy Industry) |

| Country | Costa Rica |

| Year | 2022 |

| Details | A leak from a wellhead system during operation can lead to release of line medium into atmosphere and, depending on the severity of the leak, it could lead to an unplanned and costly shutdown. Wellube maintains a stock of clamps, and our in-house manufacturing capabilities enable us to provide a quick turnaround, minimizing production loss and environmental impact. To know more, contact us |

Project Summary

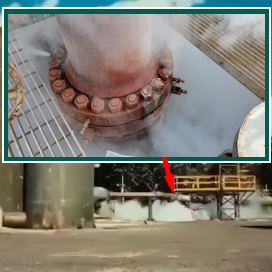

Wellube successfully executed online leak sealing at four critical locations on a steam wellhead at a geothermal facility in Costa Rica. The project demanded specialized expertise to address high-pressure (137 bar) and high-temperature (345°C) leaks. Leveraging our proven capabilities, Wellube provided an innovative solution to safely arrest the leaks, ensuring the facility’s continued safe and efficient operation under challenging conditions.

Client Requirement

The client encountered a steam leak on critical 3” to 20” flange connections on the wellhead, operating at 345°C and 137 bar. The primary requirement was to develop an engineered solution to effectively address the leak without causing any disruption to operations, loss of production, or downtime. Wellube was selected by the client due to our established reputation and proven track record in delivering reliable online leak sealing solutions for high-risk, complex applications.

Application Challenges

The leak presented multiple challenges, some of the key challenges were:

1. Extreme Temperature – To endure extreme thermal stress, high-performance sealing was required.

2. High-Pressure –The leak demanded bespoke engineered solutions for secure containment.

3. Environmental Responsibility – Minimize emissions and mitigating environmental risks at the earliest.

4. Personnel Safety Risks – High temperature and pressure posed hazards, necessitating strict safety measures.

Bespoke Solution Delivered

Wellube mobilized a team of skilled personnel to conduct an initial site survey, performing a root cause analysis, risk evaluation, and gathering critical technical data to fully understand the project conditions.

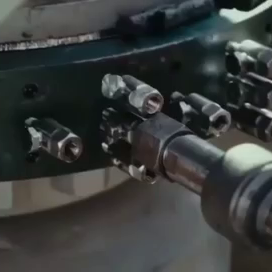

Drawing on Wellube’s global engineering expertise, a bespoke leak sealing solution was designed specifically for the site’s operational needs. Customized box and ring clamps were engineered to effectively arrest the leak at the identified locations, ensuring operational integrity under high-pressure conditions. Concurrently, the project team maintained close collaboration with the client, establishing clear communication channels from project initiation through to completion.

Upon the arrival of equipment and personnel at the site, Wellube’s team executed the leak sealing operation in strict compliance with the client’s health, safety, and environmental procedures. Following completion, a final inspection and walk-through confirmed that all project objectives were met, with the deliverables aligning fully with the client’s expectations and industry standards. The solution was successfully delivered within a seven-day timeframe, effectively minimizing downtime, avoiding production losses, and mitigating environmental risks.

Key Highlights

- Uninterrupted Operations – The project was successfully executed under live conditions, ensuring a seamless turnaround without any downtime while prioritizing personnel safety and environmental protection.

- Compliance with Engineering Standards – Designed and manufactured in full alignment with ASME standards to guarantee performance and reliability.

- Safety & Quality Commitment – Adhered strictly to QHSSE guidelines and safety protocols throughout the project’s execution.

- Local Sourcing– Incorporated locally procured materials to support the In-Country Value (ICV) framework.