More details about internal weld testers:

Features

- Easy to install and simple to use

- Self-locating

- Requires no special tools

- Reduces operational cost as minimum test medium is required

- Reduces downtime and labor costs

- Can be used on most standard pipelines

Specifications

- Non-standard sizes available

- No special tools required

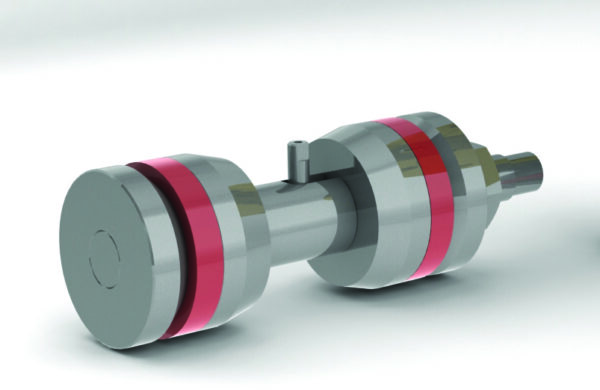

- Internal weld testers are easy to install and remove

- Self-locating capability

- Suitable for use with most test mediums

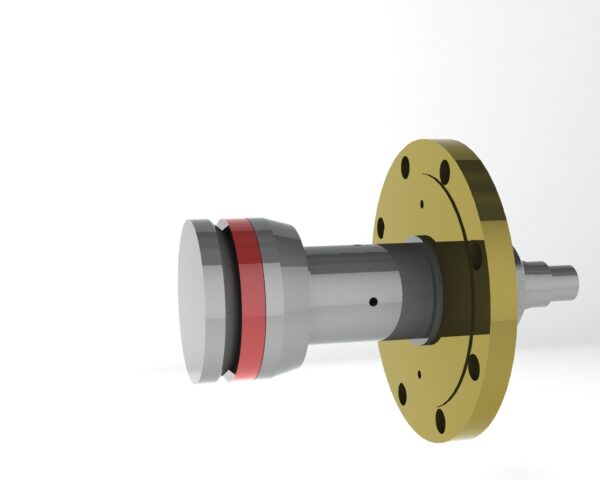

- Seals made from ‘Poly A’ Shore Hardness 85°A

- Can be used in a range of pipe schedules

- Instructions and hydrostatic test certificates supplied

Applications

- Oil & gas pipeline

- Used in hydro tests

- Downstream pipeline

Quality Internal Weld Testers from Wellube

An internal weld tester is a non-destructive testing (NDT) method used to examine and assess a welded joint’s quality. It entails inspecting the weld’s interior structure, generally using ultrasonic or X-ray techniques, to find any flaws or anomalies that could jeopardise the weld’s integrity.

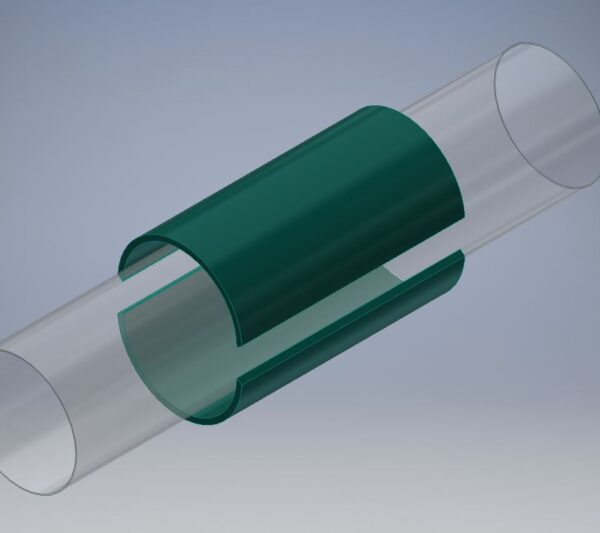

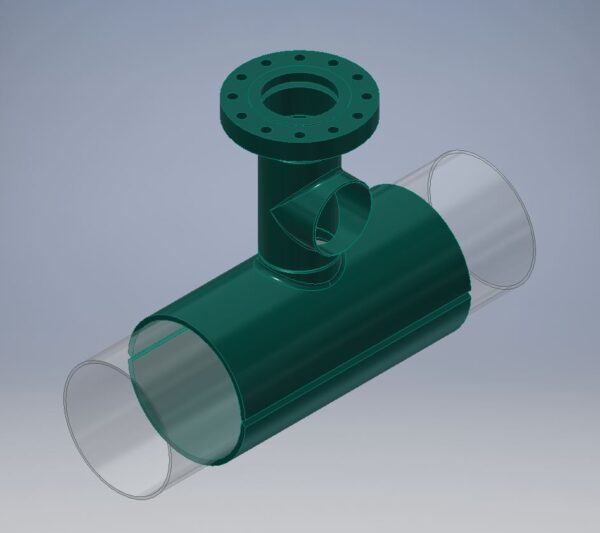

This could be an adjacent pipeline weld or a new weld neck flange. The conventional procedure would be to flood the entire pipeline and do a hydro test to demonstrate the integrity of the weld. This takes time, and it could be very expensive. The Internal Weld Tester solves this issue since it isolates the testing region and requires less time and materials.

Revealing the Secret of Internal Weld Tester Tool

Internal Weld Tester tool usage varies based on the type of tool and the specific welding application, however below is a broad outline of how an internal weld tester tool is commonly used:

- Preparing the welded joint: The welded joint’s surface is prepared by cleaning and smoothing it. This allows the ultrasonic or X-ray pulses to enter the material and produce an accurate view of the weld’s internal structure.

- Positioning the tool: The internal weld tester tool is placed on the surface of the welded joint where the examination is needed. The tool is normally positioned perpendicular to the weld, with great care made to guarantee proper positioning.

- Acquiring the data: The tool collects data by emitting ultrasonic or X-ray waves into the welded joint. These waves pass through the material and form an image of the weld’s interior structure, which is subsequently caught by a receiver.

- Analyzing the data: The tool’s data is then evaluated to find any faults or inconsistencies in the weld. This study can be performed by a qualified inspector or software that automatically detects faults..

- Reporting and Record Keeping When the analysis is finished, a report detailing the inspection’s findings is generated. This report may contain information on the location and type of problems discovered and any recommendations for repair or additional inspection. The inspection results are often recorded for quality control purposes.

Internal Weld Testing may require the use of various tools, such as ultrasonic testers or X-ray machines, and the particular techniques for employing these tools may vary depending on the tool and the welding application. Furthermore, Internal Weld Testing often necessitates specialised training and certification to verify that the inspection is performed safely and accurately.

Reduce time, cost, and downtime with Wellube’s Internal Weld Tester.

Here are some examples of how Wellube’s Internal Weld Tester can help you save time, money, and downtime:

- Our Internal Weld Tester is simple to set up and operate, offering quick and accurate non-destructive testing to ensure welded joints’ quality.

- Our Self-locating Internal Weld Testers include advanced centering technology that automatically sets the tool in the weld’s centre, ensuring precise inspections and decreasing the possibility of user error.

- Internal Weld Testers from Wellube normally require no additional tools for installation or operation, making them both convenient and cost-effective for non-destructive testing of welded joints in various industrial applications.

- Compared to other testing methods that necessitate more extensive preparation, utilise a small amount of test medium, such as water or gel, to conduct inspections, lowering operational costs and minimising waste.

- We save downtime and labour costs by detecting faults in welded joints fast and precisely, allowing for speedy repairs and reducing the need for costly and time-consuming rework.

- Internal Weld Testers are helpful equipment for non-destructive testing of welded joints in several industrial applications since they can be used on most typical pipes built from various materials, including steel and plastic

Request a quote to know more about our Internal Weld Testers and their processing, and one of our engineers will get back to you.

Availability :

Availability :