Features

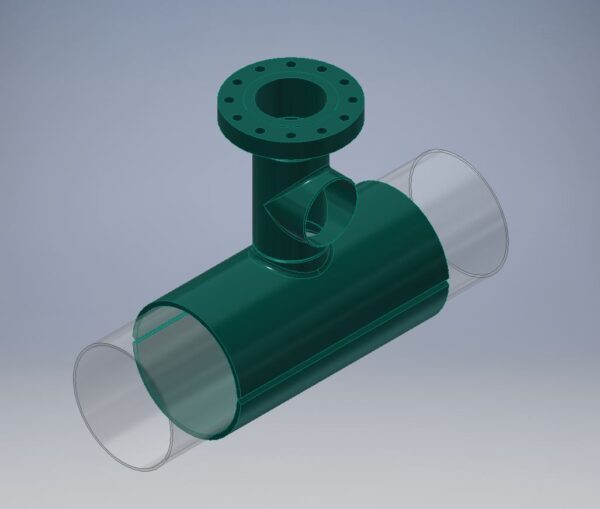

- Strengthens pipelines that are damaged against corrosion, dents, cracks, or poor welds

- Can be custom-designed as per client requirement

Specifications

- Rated AC Power Output: 7,600 VA

- Maximum AC Power Output: 8,350 VA

- AC Output Voltage: 240 VAC (211-264)

- AC Frequency: 60 Hz (59.3-60.5)

Applications

- Helps reinforce non-leaking, weakened, dented or damaged pipelines

- Also used for containing pressure application

- Used in oil & gas pipelines

Enhance pipeline durability and safety with Wellube’s tailored reinforcing sleeves

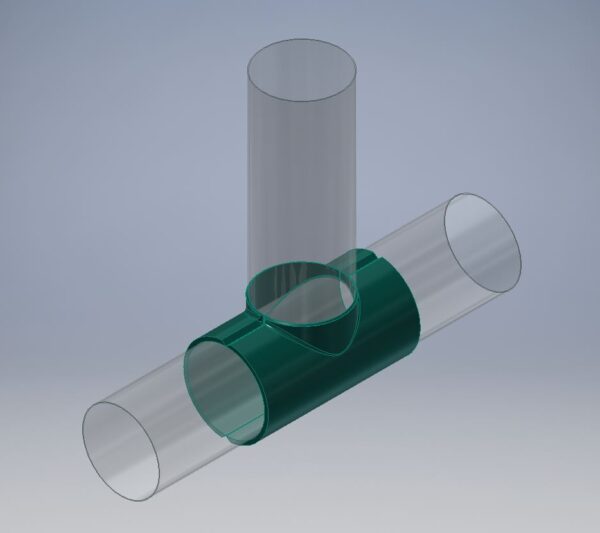

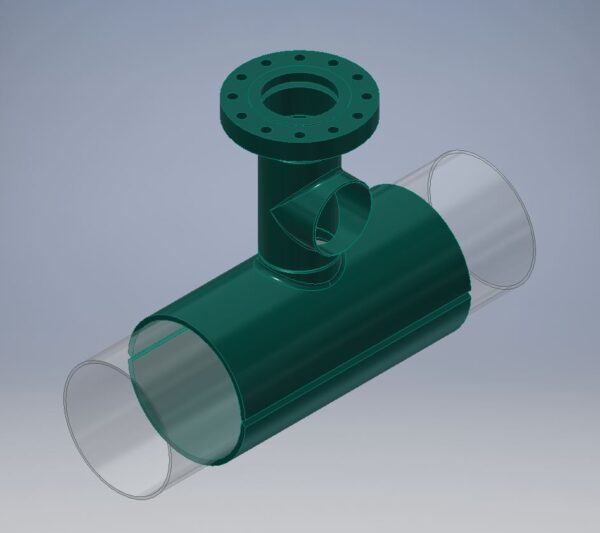

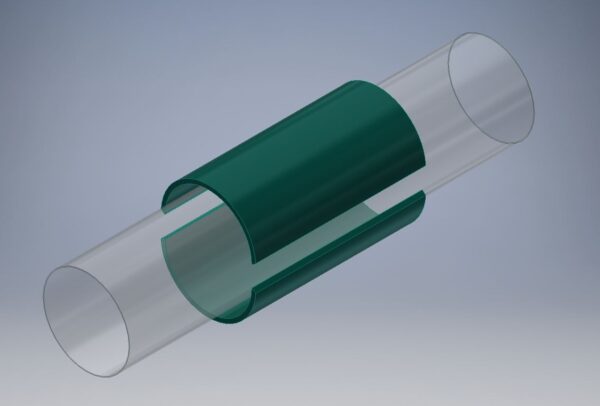

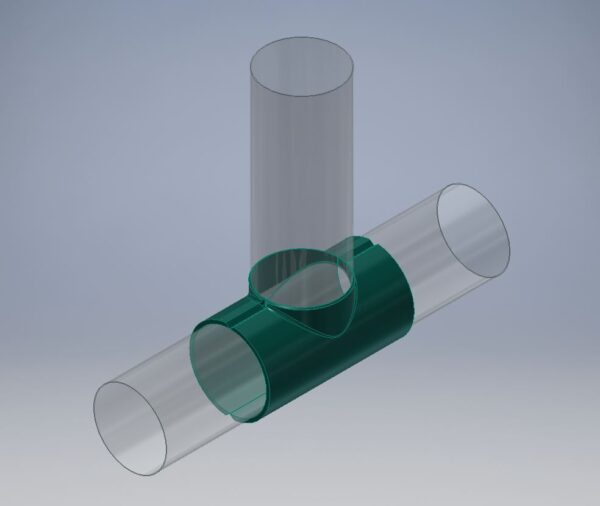

Pipelines are frequently strengthened and safeguarded with reinforcing sleeves. Usually, these sleeves are constructed from strong materials like steel or composites. They are made to be fitted around pipeline segments that could be exposed to corrosive, abrasive, or damaging external forces.

To stop pipeline leaks, ruptures, or structural failures, they provide an extra layer of security. The pipeline’s lifespan can be increased by using these sleeves to strengthen weak spots like corrosion- or damage-affected sections.

Additionally, reinforcing sleeves support pipelines’ structural integrity when exposed to high pressure. They serve as a barrier against outside factors such as settling soil, seismic activity, and impacts from excavation or adjoining building projects.

Reinforcing sleeve installation is a crucial procedure requiring careful evaluation, planning, and effective application methods. Using welding, clamping, or other authorised techniques, skilled professionals carefully attach the sleeves after performing inspections to identify places that need reinforcement.

Overall, reinforcing sleeves are essential to maintaining the efficient conveyance of resources while lowering the risks of leaks, failures, and environmental effects. They also play a critical part in improving the safety, dependability, and longevity of oil and gas pipelines.

What are “Sleeves” in the pipe?

Sleeves are typically cylindrical parts or fittings used in the context of pipes to support, shield, or transition between various sections of the pipe system. Here are two typical applications for sleeves in pipes:

- Pipe plugs, known as high-pressure Test plugs, are offered commercially by PlugCo. Their use size ranges from 100 mm to 2000 mm, and they are available for such purposes. These pipe plugs are generally employed in high-pressure applications where ordinary inflating rubber plugs cannot hold.

- A line of Pipe plugs known as high-pressure Test plugs is offered commercially by Wellube. These pipe plugs are generally used in high-pressure applications where ordinary inflating rubber plugs cannot hold.

Pipe sleeves are often built of robust materials such as steel, plastic, or composite materials, depending on the specific application and pipe system needs. They contribute significantly to the integrity, functioning, and safety of pipe networks by offering support, protection, and repair capabilities.

The process included in pipeline sleeves reinforcement

Depending on the application and the type of structure or equipment being reinforced, the technique for installing reinforcing sleeves may differ. However, below is a general summary of the reinforcing sleeve installation process:

1. Planning & Assessment

- Assess the structure or equipment thoroughly to find places that require reinforcing.

- Based on the specific needs and load-bearing capacities, select the suitable type and size of reinforcing sleeves.

3. Installation

- The surface where the reinforcing sleeve will be inserted should be treated with an adhesive or bonding agent.

- Place the reinforcing sleeve over the desired region carefully, ensuring it is properly aligned and in contact with the surface.

- Hold the sleeve in place using clamps, fasteners, or other techniques as necessary during the curing or bonding process.

- For the particular sort of reinforcing sleeve being utilised, adhere to the manufacturer’s recommendations along with the experts.

2. Preparation

- Clean and prepare the surface where the reinforcing sleeve will be put to guarantee effective adhesion and bonding.

- Debris, rust, and other materials obstructing installation should be removed.

4. Reinforcement and Curing

- Follow the suggested time and temperature parameters for the adhesive or bonding agent’s curing process.

- Ensure the reinforcing sleeve has a strong, secure bond and is securely adhered to the surface.

- Additional processes, such as applying a protective coating or carrying out load testing to confirm the efficiency of the reinforcement, can be necessary depending on the application.

5. Quality Assurance and Inspection

- Make careful inspections to make sure the reinforcing sleeves are bonded and installed correctly.

- Verify the longevity and strength of the reinforcement by carrying out any relevant quality assurance tests or evaluations.

- Deal with any problems or issues found during the inspection process.

It is crucial to keep in mind that the aforementioned phases just serve as a broad overview of the procedure; specifics and approaches may change based on the needs of the project and the kind of reinforcing sleeves being utilised. For appropriate advice and conformity to industry standards, it is advised to speak with our specialists with expertise in installing reinforcing sleeves.

Why opt for Wellube services for reinforcing sleeves?

There are various compelling reasons to consider while choosing Wellube services for sleeve reinforcement. Here are several major advantages:

- We offer expert and experienced engineers who have long worked in the field.

- We offer customised solutions.

- At Wellube, we offer quality materials and techniques.

- Our prime concern is safety.

- We take a holistic approach that guarantees the reinforcement is efficient and fits the project’s objectives.

- We offer cost-effective solutions.

- Wellube respects teamwork and keeps lines of communication open with customers.

Overall, selecting Wellube for reinforcing sleeves offers the assurance of a trustworthy and knowledgeable partner committed to delivering high-quality solutions, putting safety first, and offering top-notch customer service. To know more about the reinforcing sleeves services, get in touch with our experts today.

Availability :

Availability :