Pressure Safety Relief Valve (PSV) Testing and Its Importance

The periodic testing and calibration of PSV help to eliminate risks of potential hazards and ensures the safety of transmission pipelines. In this blog, we explore more about PSV test and its importance.

The purpose of a pressure relief valve is to control or limit surges of pressure within pipelines acting as protection for the system and defending against instrument or equipment failure. They are usually present in Mining, Offshore, Power, Oil and Gas industries.

How does Pressure Safety Relief Valve (PSV) Work?

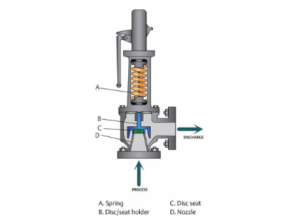

The pipelines or transmission lines operate within a definite internal process/pressure, and when it gets into an excessive state, the PSV opens to discharge the pressure and bring back the pipeline pressure to its usual state.

Generally, excessive internal pressure can be hazardous and may result in leakages or faults. PSVs help alleviates such conditions, thereby ensuring safe operations.

Types of PSV Testing

There are different types of pressure relief valve testing which are as follows:

- Online PSV Testing and calibration: This method of testing can be done while the pipeline systems are running. This method doesn’t require shutting down an existing pipeline.

- Bench Testing: This is the most popular testing method as it requires removing devices and components to ensure complete functionality. This Bench Testing is the desired way of pressure valve testing to ensure optimal efficiency.

Pressure Safety Relief Valve (PSV) Testing: Why it’s Needed?

Periodic testing of the Safety Relief Valve (PSV) is very important as it is one of the essential components that can help pipeline systems in the industry to function as per their usual specified pressures. Since fault detection is a crucial aspect, testing plays a very important role to keep the system state at the preferred level.

Understanding the Importance of PSV Testing

Here are some pointers to help you understand the importance of PSV Testing:

- Run to Failure operations may be hazardous as PSV is a safety component. Periodic maintenance is the only solution that will help in keeping all hazards and risks at bay. Periodic maintenance must be scheduled to ensure that the PSV works at an optimum level. Bench testing is one of the popular testing methods that are used to ensure the optimal efficiency of these systems.

- PSV testing can help in ensuring that various mechanical parts such as springs or discs work as usual and there is no need for replacement or repair. The spring is responsible for adjusting the pressures and if it fails the whole system can malfunction.PSV testing can also help in identifying the need for potential repairs and replacements of components.

- There may be scenarios when the valve can be rendered inefficient to manage the excessive pressure in the system. Proactive testing can help sort out such issues to ensure that it works properly.

- The disc located inside the PSV may get affected due to debris or chemical components. It is important to clean it on a regular basis which is only possible after regular testing of the PSV components.

- Performing Pressure Reading to Calibrate PSV: While installing or calibrating a PSV, there may be various conditions such as overpressure, set pressure and closing pressure that should be checked properly to ensure the safety of PSV.

- PSV Testing ensures documentation of calibration records: it can help in documenting calibration records to ensure safety compliance. This also helps in maintaining a proper check of valve systems within a pipeline network.

Conclusion

The matter of safety is paramount when maintaining pipeline systems effectively. PSV Testing should be considered as a part of the routine maintenance process to adhere to quality controls and safety compliances. As it offers varied benefits, it also ensures the optimum performance of safety controls to eliminate potential risks of hazards such as an explosion or pipeline failure. Apart from this, testing also helps in managing pipeline integrity and extends its service life in varied ways.