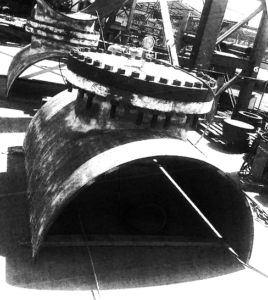

42” Hot Tapping on 48” #600 Crude Oil Pipeline and 64” #150 Ship Loading Pipeline

| Client | SK Engineering and Construction (SKEC) |

| Country | Fujairah, United Arab Emirates (UAE) |

| Year | 2023 |

| Details | Wellube’s hot tapping and line stopping service is a cost-effective way of enabling repairs, maintenance, modifications, or reconfiguration work on existing piping systems – on either a planned or emergency basis. Our hot tap operation prevents unwanted shutdowns and keeps critical piping and pipeline systems online during tie-ins, relocations, repairs, retrofits, and routine maintenance. To know more, contact us |

Project Summary

Wellube successfully delivered a comprehensive hot tapping solution, ensuring uninterrupted operations and improved reliability for a client in the marine industry. The project encompassed all phases, including design, fabrication, valve supply, and installation. Additionally, Wellube managed on-site requirements such as scaffolding, lifting, cranage, and other logistics necessary for the hot tapping operation, providing end-to-end support throughout the process.

Client Requirement

The client needed to extend their existing 48” and 64” pipelines while keeping operations online, as a complete shutdown was not feasible due to the high demand at the business facility. They required a solution that would allow uninterrupted operations of the critical high-pressure pipelines.

Challenges faced

Leveraging our advanced global engineering expertise through the “Centre of Excellence” and strong project management capabilities, Wellube quickly delivered a turnkey hot-tapping solution, adhering to the fastest project schedule possible to meet site requirements.

After the proposal was accepted, Wellube conducted a comprehensive site survey. We developed detailed weld procedures, accounting for potential breaks and flow variations, to minimize downtime. Simultaneously, the project team and key contacts established streamlined communication to expedite the documentation process and procurement, ensuring the timely sourcing of full-bore gate and ball valves. A successful Factory Acceptance Test (FAT) was then conducted on the 48” #600 pipeline.

Once all equipment arrived on-site, the Wellube team executed the hot tapping process, including the required valve installations as specified by the client. After project completion, a detailed walk-through was performed to confirm that all work had been carried out in full compliance with the client’s specifications.

Benefits Delivered

- Sourcing of materials was done locally, supporting the IN-COUNTRY VALUE (ICV) system.

- The project was completed without interrupting or halting LIVE pipeline.

- The project was executed with complete QHSSE compliance and safety.

- Completed the project on-time-in-full and as per codes.