Features

- Reduced plant operation downtime and consequent revenue stream constraints

- Reduced modification of labour time

- Fast easy installation and testing

- Versatile: Seal and washer set easily change to accommodate different pipe schedules

Specifications

- A full range of standard Flange Weld Testers is available in sizes up to 36”

- Compatible with common pipe schedules and flange configurations up to Class 2500

- Can be custom designed to suit the specific application for higher pipe sizes with the option of hydraulic and mechanical actuation

- Faster pipe repairs and retrofits

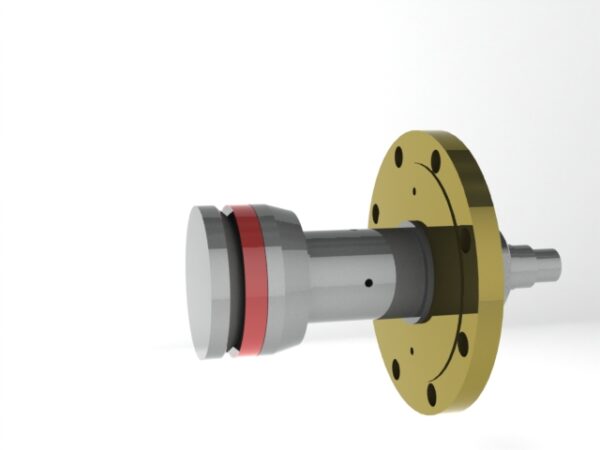

- Improved Seal-to-Pipe Clearance: The plug can be easily installed and removed, even where there are severe weld protrusions

- Low water requirements resulting in less wastewater

- Rugged, heavy-duty construction

Applications

- Creates pressure boundary on the pipe past the flange to pipe weld

- Used in pump test pressure and isolated test annulus between seals

- Used in hydrotesting weld joints

- Used in confirming joint function in piping systems

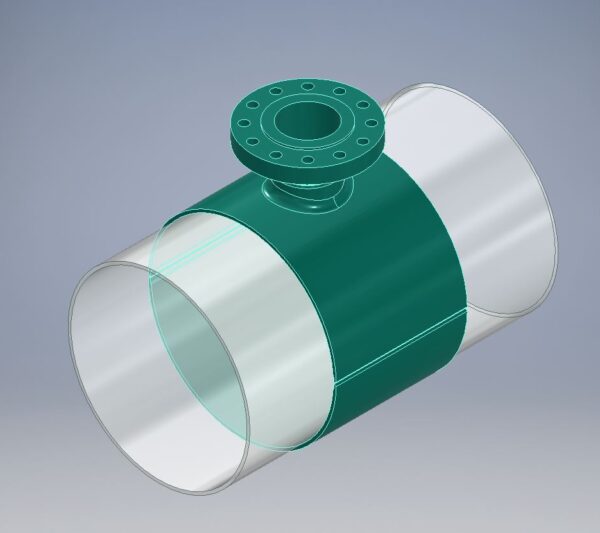

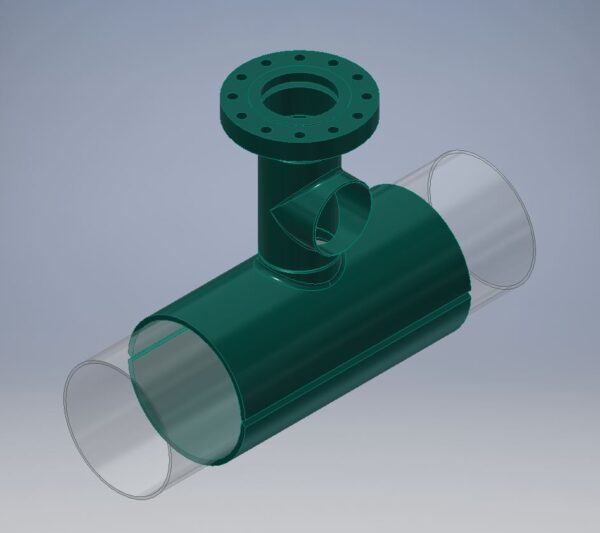

- Comes in two style: mechanical flange tester and inflatable flange tester

Efficient and Dependable Flange Weld Testers from Wellube

Flange weld testers are specialised tools used for welding flange connections’ inspection and testing. In piping systems, flange connections are frequently used to unite two distinct pipe sections. A flange is a disc or ring that typically features holes for bolts or studs. Welding the flange to the pipe sections creates a leak-tight and structurally robust connection.

Testers for flange welds are made to judge the strength and integrity of the welds in these connections. They are used to find potential flaws in the welds, like fractures, porosity, insufficient fusion, or lack of penetration. The testers aid in preventing any leaks, breakdowns, or safety dangers in the piping system by spotting these problems early on.

Why do we need a flange?

As you may know, welded joints or connections for pipes are entirely permanent. However, flange connections are typically used for joints or links that need to be occasionally removed.

Flanges are not a universally applicable option. A piping system’s intended use and idle flange design must match for the system to function properly. Flanges come in six main varieties:

- Blind Flange: This is used to seal off a pipe’s ends, preventing any flow or leaking.

- Lap joint: This joins to a pressure vessel or sealable joint, similar to how a stub end connects to the termination of a pipe.

- Threaded: This flange, which is frequently referred to as a screwed flange, can be joined without welding. This approach has advantages and disadvantages. The benefit is that you may install it without a welder by just matching the thread to the connecting pipes. The main drawback is that it may be vulnerable to leaks; hence threaded flanges are frequently utilised on smaller pipes.

- Slip-on flange: This flange is utilised to accommodate a system with a significant rate flow and is offered in various sizes.

- Socket Weld Flange: This is perfect for low-temperature and pressure systems with tiny pipe sizes. This flange joins with a socket weld to secure it to the pipe or tube.

- Weld neck: This flange can be identified by its hub on the neck, which is made to fit a pipe’s inner side. Installing a butt weld is necessary for a weld neck flange. Because it can endure high pressure and temperatures, this flange is frequently used in the pipe manufacturing. As a result, erosion and turbulence are reduced.

Techniques to evaluate the welds

Flange weld testers frequently use non-destructive testing (NDT) techniques to assess the welds. Typical techniques include:

- Visual Inspection: To do this, the welds must be visually inspected for any obvious flaws, such as fractures, undercutting, or excessive reinforcing.

- Radiographic Testing: Inspectors can find internal flaws that aren’t evident to the naked eye by using X-rays or gamma rays to build an image of the weld.

- Ultrasonic Testing: To detect flaws like cracks or a lack of fusion, high-frequency sound waves are passed into the weld, and their reflections are examined.

- Magnetic particle testing: Identifying surface or near-surface weld faults using magnetic fields and iron particles is known as magnetic particle testing (MT).

- Dye Penetrant Testing (PT): The weld surface is coated with a coloured dye, which penetrates into any surface flaws. A developer is then used to make the flaws obvious once the extra dye has been removed.

- Eddy Current Testing (ET): This technique uses electromagnetic induction to measure changes in electrical conductivity to find surface or near-surface flaws.

To conduct on-site inspections, flange weld testers are often portable tools that may be taken to the location of the flange connection. Particularly in sectors like oil and gas, petrochemicals, power generation, and construction, they play a critical role in assuring the quality and dependability of welded flange connections.

Tailored Flange Weld Testers for Specific, Appropriate, and Safe Applications

A significant advantage when modifying pipelines and repairing ageing pipework is provided by Wellube’s Flange Weld Testers, which accurately localise pressure testing of new flange welds.

That’s because they don’t test the entire system; only the new weld is tested. Given the possibility of additional leak pathways, particularly on numerous different fittings, pressure testing an old pipe can produce confused findings. For flanges installed on bends, there are also specially angled tests available.

The tool’s use minimises test system constraints and reduces the time needed to complete maintenance or modification work. The Weld Testers can also be supplied with patented “tyre”-type seals, which are suitable for testing when ovality and heavy pitting of the pipeline need to be overcome. They are often equipped with a patented Posi-Seal.

Sizes up to 36″ are offered, including a full range of standard flange weld testers that are compatible with Class 2500 flange designs and typical pipe schedules. For larger pipe sizes, they can be specially made to fit the purpose, with the choice of hydraulic or mechanical actuation.

Wellube’s Flange Weld Tester Key Features:

- Reduced plant downtime and resulting revenue stream limitations

- Reduced labour time for modification

- Quick and simple installation and testing

- Quicker pipe upgrades and repairs

- Improved Seal-to-Pipe Clearance: Even in cases with significant weld protrusion, plug installation and removal are simple.

- Less wastewater is produced due to less water consumption.

- Strong, durable structure

- Flexible: The seal and washer set can be changed to fit various pipe schedules.

FAQ’s

How do I know if my flange gasket surface needs to be serviced?

There are several signs that your flanges may need to be serviced, such as leaks, corrosion, wear, damage, misalignment, or reduced performance. You may also need flange facing if you want to connect new pipes, valves, or other components to the flanges, or if you want to improve the sealing and safety of your system.

How long does flange facing take?

The duration of flange facing depends on several factors, such as the size, type, extent of damage, and location of the flanges, as well as the type of facing machine and tool used. Typically, flange facing can take from a few hours to a few days, depending on the complexity and scope of the project.

How much does flange facing cost?

The cost of flange facing varies depending on several factors, such as the number of flanges, the type of flange facing required, the condition of the flanges, the location of the flanges, and the availability of resources and equipment. Wellube can provide customized quotes based on your specific needs and requirements.

What are the benefits of using Wellube for flange facing?

Wellube offers several benefits for flange facing, such as:

- Expertise: Wellube has years of experience and knowledge in flange facing and related services and can provide high-quality and reliable solutions for various applications and industries.

- Efficiency: We use advanced equipment and techniques to minimize downtime, reduce costs, and improve performance and safety.

- Customization: Wellube can tailor their flange facing services to your specific needs and requirements and provide comprehensive solutions from inspection and preparation to execution and testing.

- Safety: Wellube follows strict safety protocols and standards to ensure the protection of personnel, equipment, and the environment during flange facing operations.

- Support: We can provide technical support, maintenance, and monitoring services to ensure the long-term integrity and reliability of your flanges and system.

How do I know if my flange gasket surface needs to be serviced?

There are several signs that your flanges may need to be serviced, such as leaks, corrosion, wear, damage, misalignment, or reduced performance. You may also need flange facing if you want to connect new pipes, valves, or other components to the flanges, or if you want to improve the sealing and safety of your system.

How long does flange facing take?

The duration of flange facing depends on several factors, such as the size, type, extent of damage, and location of the flanges, as well as the type of facing machine and tool used. Typically, flange facing can take from a few hours to a few days, depending on the complexity and scope of the project.

How much does flange facing cost?

The cost of flange facing varies depending on several factors, such as the number of flanges, the type of flange facing required, the condition of the flanges, the location of the flanges, and the availability of resources and equipment. Wellube can provide customized quotes based on your specific needs and requirements.

What are the benefits of using Wellube for flange facing?

Wellube offers several benefits for flange facing, such as:

- Expertise: Wellube has years of experience and knowledge in flange facing and related services and can provide high-quality and reliable solutions for various applications and industries.

- Efficiency: We use advanced equipment and techniques to minimize downtime, reduce costs, and improve performance and safety.

- Customization: Wellube can tailor their flange facing services to your specific needs and requirements and provide comprehensive solutions from inspection and preparation to execution and testing.

- Safety: Wellube follows strict safety protocols and standards to ensure the protection of personnel, equipment, and the environment during flange facing operations.

- Support: We can provide technical support, maintenance, and monitoring services to ensure the long-term integrity and reliability of your flanges and system.

Availability :

Availability :