Wellube Performs High Pressure Gate Valve Milling on Wellheads to Regain Access into Annulus

| Country | UAE |

| Date/ Year | 2019 |

| Service Details | Wellube offers high-pressure gate milling services to help clients regain access to the wellheads by drilling through the stuck gates to restore operations. We can also customize the solution based on your requirements, reach out to us with your operational challenges enquiries@wellube.com |

Summary of the Project

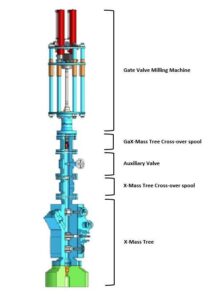

Wellube performed high-pressure gate valve milling of multiple stuck gates of X-mas trees on the onshore wellheads of a leading asset owner in the UAE, helping the client restore production with minimal downtime.

Client Requirement

The client was facing the loss of production due to inaccessible wells and was looking for ways to solve this issue. Wellube after analysis of the challenges provided the client with the solution to perform milling on the stuck gate valves of the X-mas trees. This was accepted by the client’s technical team and a first of its kind call off agreement was signed by the asset owner and Wellube to help the client tackle the issue and ensure continuity in operations and oil production.

Challenges Faced

We faced challenges pertaining to the timeline and operational accessibility of the project as

- Most of the X-mas trees were spread across rough and sandy terrain in the desert wherein access and support facilities were limited. We had to mobilize a containerised office and workshop to complete the works at site without delays.

- This was a turnkey project wherein the support high-pressure gate valve milling services were also part of the scope of supply and mobilisation of trailers and cranes to undertake the project was challenging.

Unique Solution Delivered

Wellube delivered high-pressure gate milling as the best solution for the client as it drills through the toughest and thickest gates available in the market for X-Mas trees. This helped regain access into the well annulus for stuck gates to provide a full-bore access. We have completed drilling on 5 wellheads milling a total of 7 stuck valves including the Upper Master and Lower Master Valves with additional valves in the pipeline.

We provided high-pressure gate valve milling, a turnkey project management solution, with our experienced technical team covering a wide range of trees and strings with pressures ranging from 5,000 psi to 10,000 psi and sizes from 2” to 6” gates. As the job sites were in remote rough terrains, we set up a containerised workshop and office for quicker response time and less downtime for the client.

Benefits Delivered

- One stop solution as it was a turnkey project covering all aspects of site requirements.

- Quick turnaround to site enabled them to resume production in minimal time.

- Multiple milling jobs were undertaken in a single mobilisation thus minimising the downtime.

- The project was completed with zero incidents and fully HSE compliant.