Maintain and repair the pipelines with Wellube’s special fitting procedure.

Several pipeline custom fittings are frequently utilised in oil and gas piping systems to satisfy the unique needs and difficulties of carrying petroleum products and gases. Here are a few instances of these fittings:

- Flanged connectors

- Ball Valves

- Check Valves

- Pipeline pigs

- Pressure Relief Valves

- Expansion Joints

- Pig Launchers & Receivers

- Strainers/Filters

Pipeline size, pressure, temperature, product properties, and industry norms all influence fitting selection and use.

Uni-Forge engineers may provide a unique solution to meet your specific needs. Three-way connections, angle fittings, and more options are available. We’ll take the time to understand your problem, work through budgets and timelines, and deliver the correct solution at the right time.

Types of special fittings

Technical engineers at Wellube work at unique solutions to meet your needs. This includes:

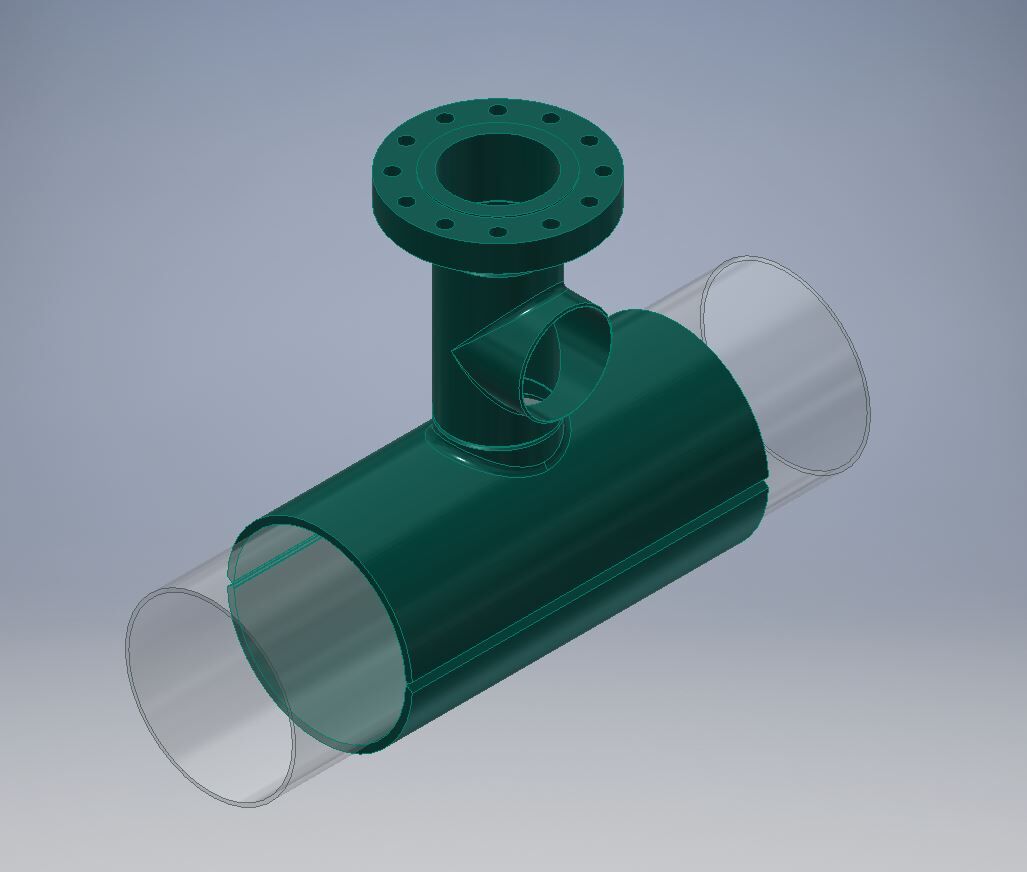

- Three-way connection: Three-way fittings, also known as tee fittings, divide a pipeline into three separate branches or join three pipelines into a single line. These connections allow fluid or gas flow to be redirected in different directions, enabling flexibility and diversity in pipeline construction. Three-way fittings are frequently used in distribution networks, process systems, and pipeline layouts when branching or merging is required.

- Angle fittings: Angle fittings, also known as elbow fittings, are used to alter the pipeline’s direction at different angles. They allow for seamless changes in pipeline direction while minimising pressure drop and preserving flow efficiency. Curvatures range from 45 degrees to 90 degrees. Oil and gas pipelines that have to go around obstacles or change course to meet the infrastructure’s layout often benefit from angle fittings.

Industrial Application of special pipeline fitting

Special pipeline fittings are widely used in a variety of industrial fields. Here are a few significant industrial uses for customised pipeline fittings:

- Oil & Gas industry

- Chemical industry

- Water & wastewater treatment

- Power generation

- Pharmaceutical

- Food & Beverage Industry

- Mining & Minerals

Process Includes

- The pipeline system must first be designed and planned. This involves figuring up the required pressure, layout, and any necessary branching or directional changes, as well as the desired flow rates. These design factors inform the choice of these specific fittings.

- Following the creation of the pipeline design, suitable fittings are chosen under the demands. When a pipeline needs to be split into three independent branches or united into one line, three-way fittings, sometimes called tee fittings, are used. Angle fittings, also known as elbow fittings, are chosen when varying angles call for direction adjustments.

- According to the pipe diameter and flow requirements, the chosen fittings are sized. To accommodate diverse pipe dimensions and angles, fittings come in various sizes and combinations. The manufacturer’s suggestions and the pipeline design are used to determine the precise sizes and configurations.

- Then, in accordance with the planned layout, the fittings are put into the pipeline system. To do this, the pipe must be cut at the required locations, and the fittings must be connected using the proper techniques, such as welding, threading, or flanging. To avoid leaks or structural problems, care is taken to guarantee adequate alignment, sealing, and connection integrity.

- Following the installation of the fittings, the pipeline system is tested and inspected to guarantee its reliability. This could involve visual inspection of the fittings and connections, pressure testing, and leak detection. Any problems or shortcomings found at this phase are addressed and fixed.

- The pipeline system is included in the broader industrial process or infrastructure following successful testing and inspection. To ensure accurate flow control, monitoring, and pipeline functioning, valves, pumps, control systems, and other components may be used.

- To ensure long-term dependability and safety, the pipeline system must undergo routine maintenance and monitoring, including specific fittings. To do this, it may be necessary to perform routine inspections, clean the area, and replace any worn-out parts.

Why trust Wellube for special fitting services?

With years of experience and dependability in the industry, Wellube is a dependable supplier of special fitting services. Wellube distinguishes itself as a trustworthy option for pipeline solutions with a dedication to quality and client satisfaction.

At Wellube, the emphasis is on providing great service designed to meet each client’s needs. They know how critical accuracy and effectiveness are while providing bespoke fitting services. Every project is carried out to the highest standard of expertise thanks to their team’s significant knowledge and experience in pipeline systems.

Safety comes first and foremost. To guarantee a safe working environment for both their team and the staff of the customer, they strictly adhere to safety rules and industry requirements. The dedication of Wellube to safety is seen in their ongoing training programs, which keep their technicians abreast of the most recent industry practices and protocols.

Their customer-focused philosophy, technical proficiency, dedication to safety, and emphasis on human-centred design make them a dependable option for any pipeline-related requirements.