Features

- Coded for material identification and traceability

- Provided with material certificates

- If required, we can also perform Hydrostatic Testing, Ultrasonic Testing, Radiography Testing, Magnetic Particle Examination, and Destructive & Non-Destructive Testing

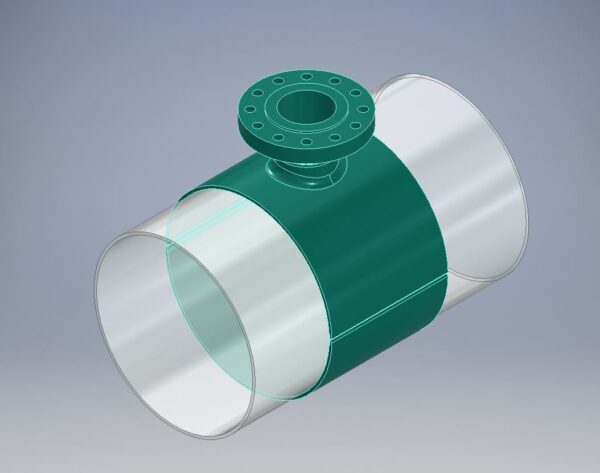

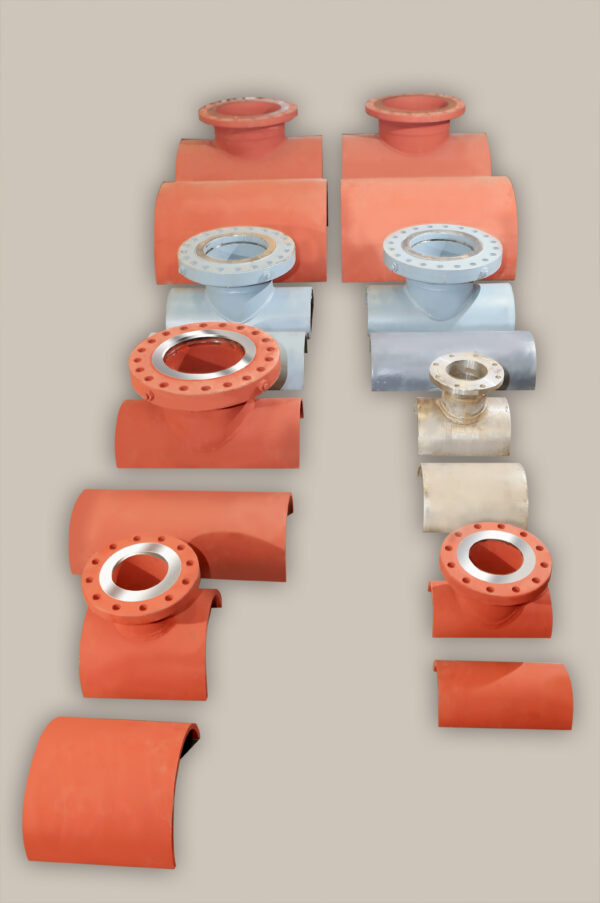

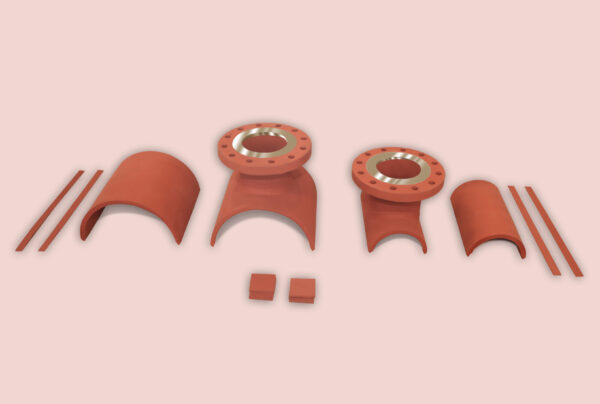

- Based on pipeline size and specifications, the hot tap fitting can be provided with a different reinforcement such as a weldolet or pad

- Manufactured and delivered to your quality control specifications

Specifications

- Available in a wide range of sizes, from 2” to 48″

- Fittings are equipped with a welding neck flange RF according to ANSI Class 150, 300, 600 or 900

- Larger sizes and pressure ratings are available to meet any need

- Fittings are available with a reducing branch to connect pipelines of varying sizes

Applications

Maximising Pipeline Efficiency with Wellube’s Hot Tap Fittings

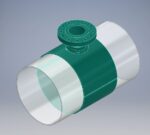

The ability to safely drill or cut into a pressurised system while in flow and under pressure is known as hot tapping or hot tapping.

In a different technique known as “hot tapping,” a new pipeline connection is made while the existing pipeline still carries natural gas under pressure. In the hot tap technique, a branch connection and valve are attached to the outside of a functioning pipeline, the pipe-line wall is then cut within the branch, and the wall section is removed through the valve. Hot tapping prevents product loss, methane emissions, and interruptions in customer service.

To secure a successful hot tapping, a typical operation requires the following equipment:

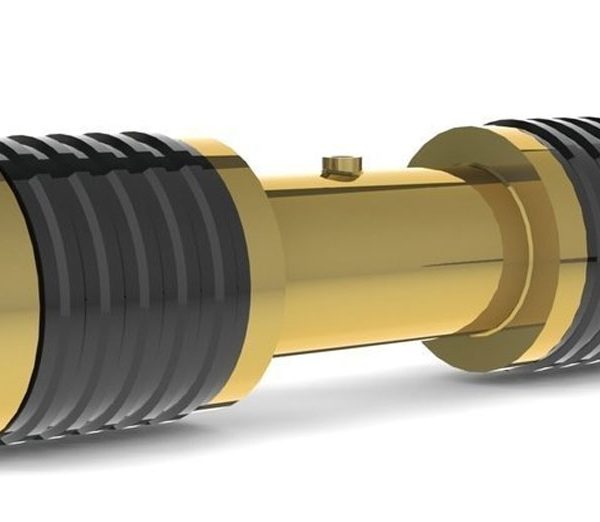

- Drilling machine: A cutting tool is often controlled by a telescopic boring bar that is mechanically powered by the drilling machine. To centre a hole saw that removes the “coupon,” or curved part of the pipeline wall, the cutting tool is used to drill a pilot hole into the pipeline wall.

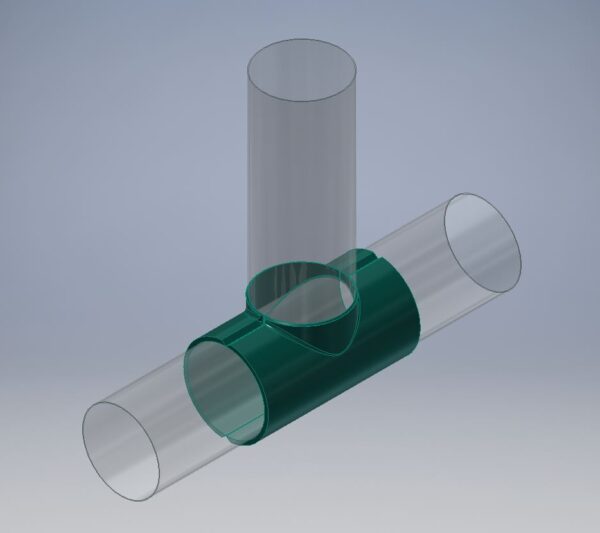

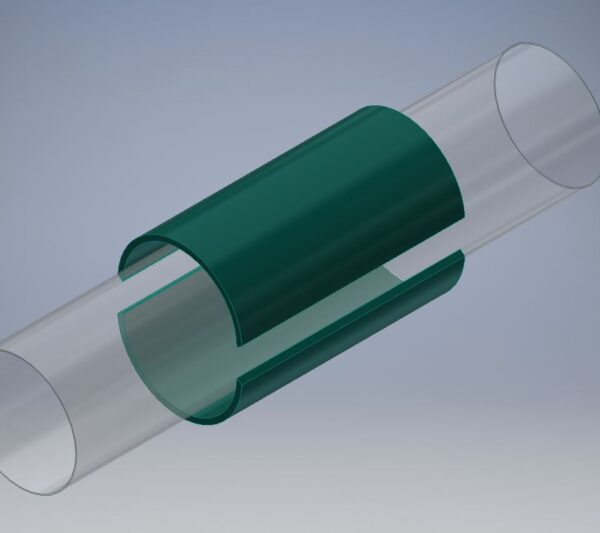

- Fittings: For a small (e.g., one inch) connection to a larger pipeline, the connection is made in a fitting, while for a branch, the parent pipeline is the same size, the fitting is a full-encirclement split tee. Ties provide mechanical reinforcement for carriers and branches when they are welded together.

- Valve: Depending on the connection, the valve can be a control valve or a block valve, but it must allow the coupon to be removed (part of the pipeline wall removed by the drilling machine) after cutting. It is OK to use a ball valve or gate valve but not a plug valve or butterfly valve.

The good news is Wellube has it all from start to finish. We provide a complete solution from the hot tap fittings, to valves, to drilling machines and a complete turnaround solution to execute the simplest to most complicated hot tapping operations.

Secure your hot tap operations with Wellube’s hot tap fittings

- Full branch split tees from Wellube are designed for equipment tie-ins, lateral connections, and line extensions using a permanent full-bore valve without shutdown.

- Wellube can meet your hot tap tee demands with tailored customer service and on-time delivery.

- Our fittings have a decreasing branch to join pipelines of various sizes. Learn more about the availability of our fittings by sending us an enquiry.

- Our fittings are available in various diameters ranging from 2″ to 48″ and are furnished with an ANSI Class 150, 300, 600, or 900 welding neck flange. Larger diameters and pressure ratings are available to accommodate any requirement.

Availability :

Availability :