How To Protect Your Fittings Against Corrosion?

According to recent studies, the cost of corrosion to the global oil and gas industry is believed to exceed over USD 60 billion, this includes the cost of maintaining these assets and the unfortunate cases of loss of production. Corrosion also has far-reaching effects on the environment and an increased risk to life, so asset owners must constantly take initiatives to prevent corrosion, wax tape, and actively include protection solutions in their maintenance calendars.

Let us consider a pipeline in atmospheric conditions, many elements associated with the pipeline are subject to corrode quickly because they are not protected with a coating or the existing coating is damaged. Among them, the most common parts are flanges, bolts and supports. These elements cannot be properly protected before delivery as they have to be assembled on-site and also because the operation of the pipeline creates small movements (e.g., pipeline expansion). The corrosion is induced by different sources like dissimilar metal contacts, corrosion protection damaged during assembly and accelerated by the corrosive atmosphere.

With years of experience in the industry, Wellube is aware of these challenges faced by clients as a result of which we have partnered with Trenton to offer simple, efficient and field-proven solutions: Wax Tape® anti-corrosion wrap system. The system is based on wax technology which is UV resistant and very easy to apply.

Understanding Wax Tape®

For clients to apply the Wax-Tape® anti-corrosion wrap system to their assets, they must follow three easy and quick steps:

- The surface on which the system needs to be applied must be cleaned, a simple surface preparation to remove all loose parts (ISO ST2 or SSPC SP2) is enough.

- The first layer of the system is a primer, which is applied by hand on the surface to be coated. The role of the primer is to displace the moisture of the substrate and create the first layer of corrosion protection. It is compatible with most of the substrates like carbon steel, stainless steel, galvanized steel, paint, concrete, PE or PP. There is no requirement to create a specific surface profile.

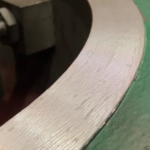

- On top of the primer, the Wax-Tape® is applied as a second barrier against corrosion. Wax-Tape® is a felt tape saturated with microcrystalline wax. It is highly conformable to be shaped to the fitting geometry and does not require any filler. Wax-Tapes are wrapped around the substrate to protect with a 1” overlap.

The system does not require any curing and corrosion protection begins as soon as the substrate is coated. As the wax is highly hydrophobic, it can be applied on wet and condensing surfaces, additionally, relative humidity during or after the coating is also not an issue.

Typical Applications of The Anti-Corrosion wrap system

Flanges

Protecting flanges with Wax-Tape anti-corrosion wrap protects the flanges elements, the bolts and the space between the two flanges. Wax Tape will not hide a leak of the flange, it will be visible even through the system.

Supports

Support systems, e.g., welded bed or U-bolt systems, can be encapsulated very easily. The Wax Tape overlapping on the pipeline coating will ensure that no corrosive factor (air, water, electricity) can reach the substrate. If the pipeline is subject to expansion, a special wrapping application can be used to allow up to 40mm of displacement.

Bolts

Bolts require a coating that can be easily removed when access to it is required, for example, manhole closure. Wax-Tape® systems applied on such surfaces are easy to remove and only require a “rag cleaning” of the screw before manipulation. If the bolt system is protected, then there will be no corrosion and it will be easier to unscrew.

Reasons to choose Wax-Tape® for your fittings

– Reliable and field-proven technology

– Easy to apply, high-skill applicators are not required

– Simple surface preparation – power tools or abrasive blasting machine is not required

– Can be applied on wet surfaces

– Logistics: No mastic/filler-less material to be carried to the site – ease of calculation for the requested material

– Easy to inspect and remove

We also provide consultations to understand client requirements and provide customised solutions based on the condition of the assets and the budget. If you are looking for a cost-effective anti-corrosion system, connect with us at enquiries@wellube.com and we will help you choose the right solution.