Features and Benefits

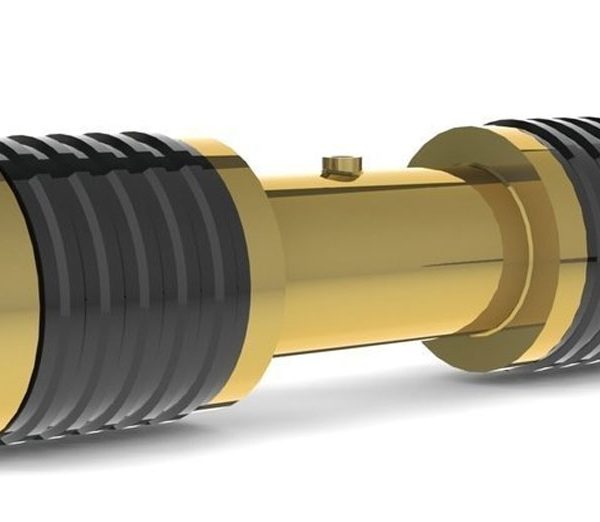

- Standard clamps include a high-quality elastomeric seal constructed of Buna-Nitrile or Viton. The sealing load is achieved in these applications by bolt tensioning the clamp studs (2 part design).

- Prior to commissioning, all Clamps are designed with an external pressure test facility to check joint integrity.

- A dual seal arrangement is also available to allow for inter-seal testing during installation.

- Clamps can be supplied for both topside and subsea repairs.

High Pressure Repair Clamps – Fast and Easy Installation on Repair Work on Pipelines

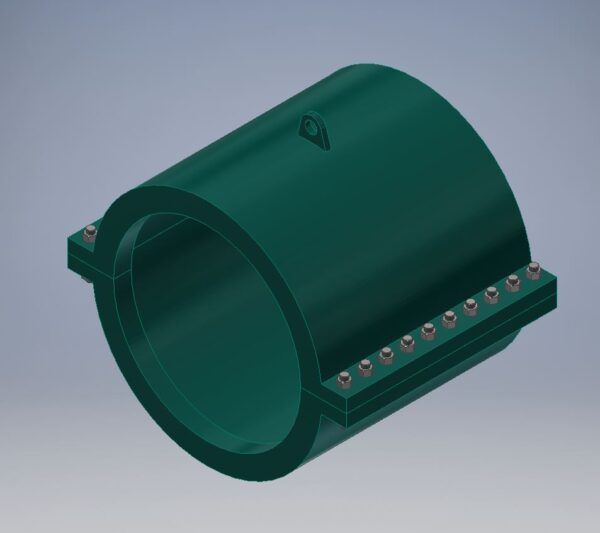

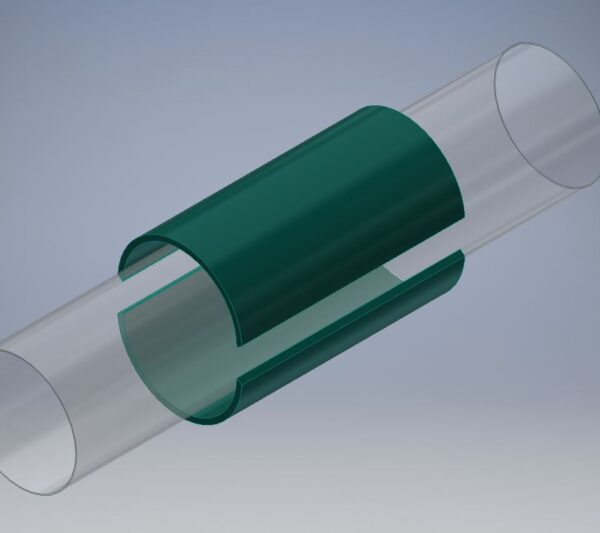

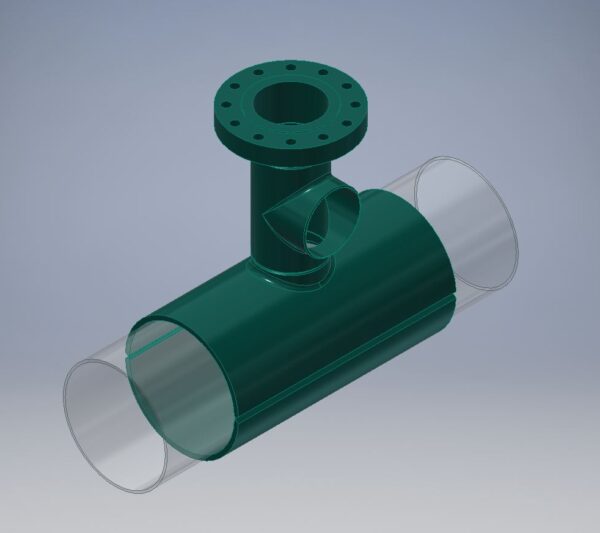

- High Pressure Repair Clamps are a quick and effective solution to repair a pipeline without cutting out and replacing the damaged part. Clamp product lines can be delivered as leak sealing or structural capabilities, with graphite or elastomeric seals to meet your individual application in terms of temperature, pressure, and pipe media.

- Moulded elastomer seals of the finest quality are used for sealing and are chosen for compatibility with the pipeline product and operation temperature. If the circumstances warrant it, the High Pressure Repair Clamps can also be welded after installation to create a permanent seal.

- Oil and gas pipeline leaks brought on by corrosion or damage can be stopped with wellube high pressure repair clamps, a type of repair fitting that can be used on land and in the water. High pressure repair clamps are appropriate for oil and gas pipelines with working pressure up to 1000 psi since they use nitrile rubber as the sealing material. Installing these high pressure repair clamp is simple. The pipeline does not need to be shut down once the clamps have been installed properly and the leak can be halted without welding. The pipeline is not welded to the clamps. At the inspection and maintenance cycle, they can be taken out, modified, and then given back to the customer if necessary. There are several different configurations of high pressure repair clamps, including pipes, elbows, tees, and crosses.

- Your interim and long-term repairs on pipelines take on a new level with the use of high pressure repair clamps. They are used to fix pipes conveying water, chemical process fluids, steam, and liquids at both high and low temperatures and pressures, both offshore and on land.

- High pressure repair clamps use their main body to cover the damaged areas of the pipeline and mechanically repair the equipment leaking. They find and repair any leaks in the faulty part. Repair clamps can be used to give either temporary or permanent solutions. Their service life is comparable to that of the system’s other piping components.

- High pressure repair clamps can be used to fix pipe leaks or thinned pipe walls. They are self-sealing because clamping studs are bolted together. The standard clamp has a single sealing configuration, however it can be upgraded to a double sealing arrangement if necessary. They are hydraulically tested to 1.5 times the clamps’ design pressure (or to client specifications). They are frequently employed in undersea and superstructure repair. The clamps include wedge grooves to prevent them from slipping during installation. If the customer requests it, we may create unique designs to repair curved pipe sections and pipe joints.

Benefits of High Pressure Repair Clamps

- Can be applied to situations including leaking pipes or thinning walls.

- They are self-sealing thanks to the clamp studs being bolted together.

- Standard clamps have a single seal configuration, however, on request, a double seal design is available.

- Wedge-shaped grooves are present to prevent seals from slipping during installation.

- 1.5 times the clamp design pressure hydro tested (or to your specifications).

- Widely employed for topside and subaerial repairs

Trust on High Pressure Repair Clamps

Wellube Clamps are the optimum solution for pipeline repair and are designed to be installed with the most commonly available tools.

We provide our clients with personalised customer care tailored to their project requirements and high-quality products

High Pressure Repair Clamps Application

- Pharmaceutical

- Power generation

- Heat exchanger

- Marine application

- Petrochemicals

- Specialty chemicals

- Architectural applications

- Offshore and Onshore

- Chemical process and water

Safety

The clamps are hydrostatically tested to 1.3 times the rated working pressure and are fully compensating pressure vessels.

Wellube – The best service provider

Because they fully understand their clients’ demands, Wellube is widely regarded as the top service provider for High Pressure Repair Clamps. They bring a lot of expertise to every project with their team of experienced specialists. They prioritise the use of high-quality, long-lasting repair clamps, delivering a dependable and long-lasting solution for damaged pipelines. What distinguishes Wellube is its dedication to personalised service. They take the time to learn about each customer’s specific needs and personalise their solutions accordingly. Wellube has established a reputation as the go-to provider for High Pressure Repair Clamps due to their commitment to client satisfaction.

Availability :

Availability :