Minimize downtime and maximize efficiency 20+ years of line stopping expertise across UAE, Qatar.

Line stopping, or line plugging, is an advanced pipeline intervention technique that utilizes a mechanically deployed stopple head to temporarily isolate a designated segment of a live pipeline. This isolation facilitates critical maintenance or repair work downstream without disrupting overall operations. By integrating permanent or temporary bypass with line stopping solution, continuous production is ensured while the isolated section is serviced.

Engineered for versatility, line stopping is indispensable during tie-ins, relocations, retrofits, and routine maintenance, preserving the operational integrity of vital pipeline systems.

Line stopping solution is effective across a broad range of pipeline materials and media—including gas, oil, water, sewage and steam—by precisely controlling flow within active pipelines.

When combined with a bypass system, the remainder of the pipeline continues to function normally, thereby eliminating unscheduled shutdowns.

While the foundational principles of line stopping date back to early 20th-century innovations, modern advancements have significantly enhanced its performance, reliability, and safety.

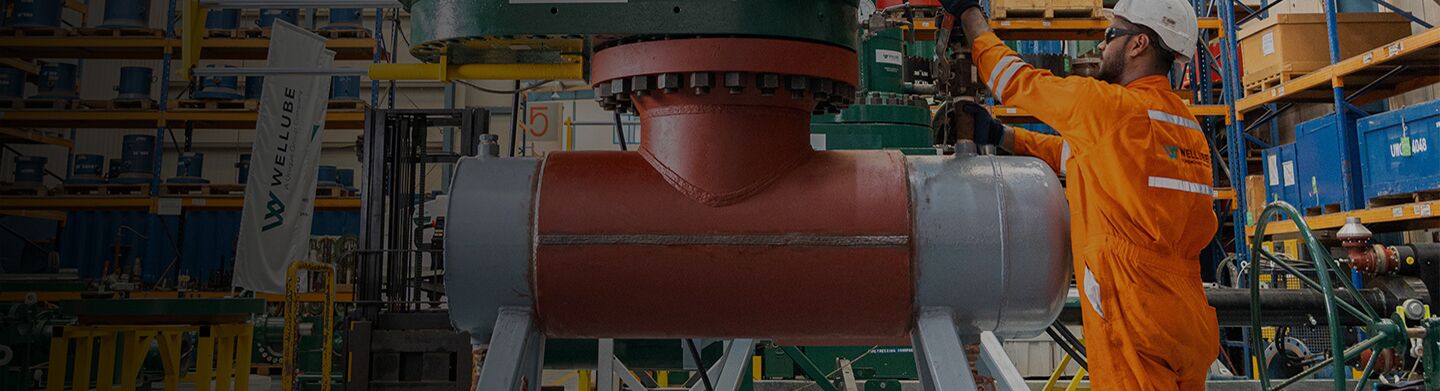

With over two decades of specialized experience across diverse industrial applications, Wellube has refined its line stopping methodology to accommodate the unique regulatory frameworks and operational challenges present in the UAE, Qatar markets. Our comprehensive approach encompasses everything from initial site assessment and engineering design to equipment fabrication, field deployment, and post-intervention certification—providing clients with a truly turnkey solution for maintaining operational continuity even under the most challenging circumstances.