Preserve pipeline integrity & avoid downtime with Wellube - Your Trusted Contractor for Hot Tapping Services.

Hot tapping, commonly referred to as pressure tapping, is a way to attach to a pressurised system, like a pipeline or pressure vessel, without taking the pipe or tank out of operation (either through drilling or cutting). This keeps operations going while preventing expensive and potentially dangerous environmental concerns.

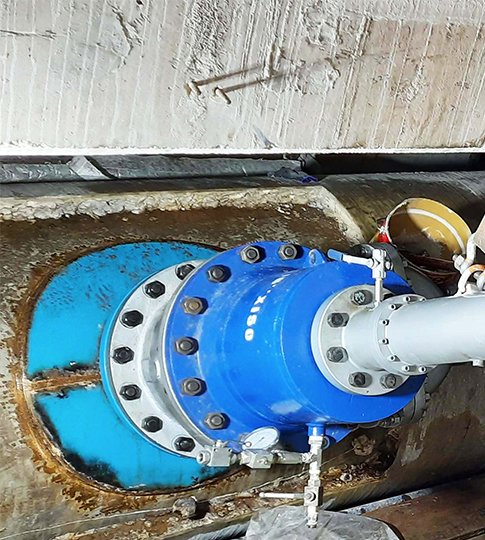

Installing connections to pipes while they are still in use is known as “hot tapping.” It is frequently used in the context of welding for any welding onto equipment that is already in use. The hot tapping process is often used to add branches to an existing system or to repair mechanically damaged or corrosion-damaged areas. Executing this welding without taking a pipe out of operation and potentially releasing significant amounts of greenhouse gases, such as methane, has clear economic and environmental benefits.

Using computer heat flow modelling methodologies and flow loops, safe hot tap welding procedures can be developed. This strategy includes matching and controlling the cooling capacity of the live pipeline, which may be measured.