Your Trusted Hot Tapping Contractor for Uninterrupted Pipeline Operations in Qatar

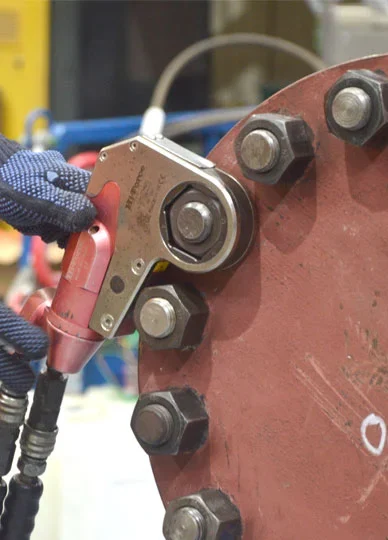

Avoid costly shutdowns and reduce your potential environmental impact with Wellube’s professional hot tapping services. As a leading hot tapping company in Qatar, we understand the importance of maintaining operational continuity. Our specialized technique allows us to safely connect to pressurized pipelines and vessels without interrupting your critical operations.

Hot tapping is a vital process for adding branch lines to existing systems or repairing damaged sections while the system remains online. By eliminating the need for shutdowns, Wellube helps you avoid significant economic losses and prevents the potential release of the line medium, contributing to a more sustainable operation.

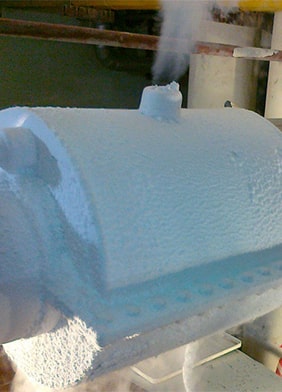

To ensure the highest levels of safety and reliability, Wellube employs sophisticated computer heat flow modelling and flow loops to develop precise hot tap welding procedures. This approach allows us to effectively manage the thermal dynamics of the live pipeline.

Hot tapping is also commonly referred to as line tapping, pressure tapping and cold tapping.