Understanding Flange Facing And Its Applications

In the oil and gas industry, flanges are essential components used to connect pipes and other equipment in various applications. A flange is a protruding rim or collar that attaches one object to another by bolting them together. However, flanges need to be properly aligned and prepared to ensure a leak-free connection. This is where flange facing services come in handy. In this blog, we will discuss flange facing, its benefits, and various applications in the oil and gas industry.

What is Flange Facing?

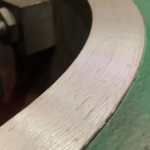

Flange facing is the process of machining the surface of a flange to achieve a smooth, flat surface. This process is necessary to ensure a leak-free joint between two flanges. Flange facing removes any surface imperfections, such as corrosion, burrs, or unevenness, which may cause leakages, resulting in loss of product, damage to equipment, and potential safety hazards.

At Wellube, we perform in-site flange facing for clients where our experienced technical specialists visit the client site with our equipment and does the complete operation of resurfacing flanges by machining at their location and providing the customers with a perfect seal. Clients highly seek after our onsite flange facing services as they reduce costs and improve project time for customers.

Benefits of Flange Facing Services

-

Leak Prevention:

The primary benefit of flange-facing services is that it helps prevent leaks. By removing surface imperfections and creating a smooth, flat surface, flange facing ensures a secure and tight seal between flanges, reducing the risk of leaks and potential environmental damage.

-

Improved Equipment Performance:

Flange facing helps maintain equipment performance by ensuring that connections are secure and leak-free. This helps to improve equipment reliability, reduce downtime, and increase production efficiency.

-

Safety:

Flange-facing services play a crucial role in ensuring the safety of workers, equipment, and the environment. By creating a tight and secure seal between flanges, flange facing helps prevent potential safety hazards, such as fires or explosions, caused by leaks.

-

Cost-Effective:

Flange-facing is cost-effective for maintaining and improving equipment performance. By preventing leaks and reducing downtime, flange facing helps to increase equipment reliability and productivity, reducing maintenance and repair costs.

Applications of Flange Facing in the Oil and Gas Industry

-

Pipeline Connections:

Flange-facing is used to prepare flanges for pipeline connections. Flanges are used to connect pipelines, valves, and other equipment, and flange facing ensures a secure and tight seal between the two surfaces, preventing leaks.

-

Refineries:

In refineries, they are used to prepare flanges for equipment connections, such as heat exchangers, distillation columns, and reactors. Flange facing ensures a leak-free joint and helps to maintain the reliability and efficiency of the equipment.

-

Offshore Platforms:

Flange-facing services are used on offshore platforms to prepare flanges for equipment connections, such as pumps, compressors, and separators. Flange facing ensures a secure and tight seal between flanges, reducing the risk of leaks and potential environmental damage.

Wellube’s expert onsite machining specialists have decades of experience working across a wide range of industries, from oil and gas to utilities, thus ensuring your machining requirements are all handled thoroughly from end to end.

Flange-facing plays a crucial role in the oil and gas industry, ensuring the reliability and safety of equipment and preventing environmental damage. By providing a cost-effective solution for maintaining and improving equipment performance, flange-facing services are an essential part of any maintenance program in the industry.

With decades of experience and the best quality equipment, we at Wellube are well-positioned to support your requirements across all industries and project specifications. We bring flange facing to your project location, thus ensuring your shutdown and project timelines are always on time and often even ahead of schedule.

If you have an upcoming requirement for flange facing, feel free to contact our technical team, and we will help you plan your project and help your assets achieve the best seal.